At present, most companies do not equip the inspection machine for the blister molding line, but visually inspect it during the packing process. However, in the future many companies will switch to automatic packaging, so visual inspection is not possible. Vietnam is a country with particularly strict quality standards in ASEAN. The blister packs with foreign objects, broken pills, chipped, etc. are all defective products. That’s why, Vuletech will introduce to you the machine to check blister packs and abnormalities on tablets.

I. What is the blister and malformation tester on tablets?

- A system that uses electronic eyes to read foreign objects, defective products, etc. during the packaging process.

- When it detects, it will automatically eject that blister pack.

II. About CKD:

CKD, one of the leading manufacturers of pharmaceutical packaging machines, based on its experience in Japan, launched a PharmVission PV610 external particle inspection machine for blister and tablet form.

With an extremely strict drug market, CKD contributes to improving the quality of blister packs for businesses.

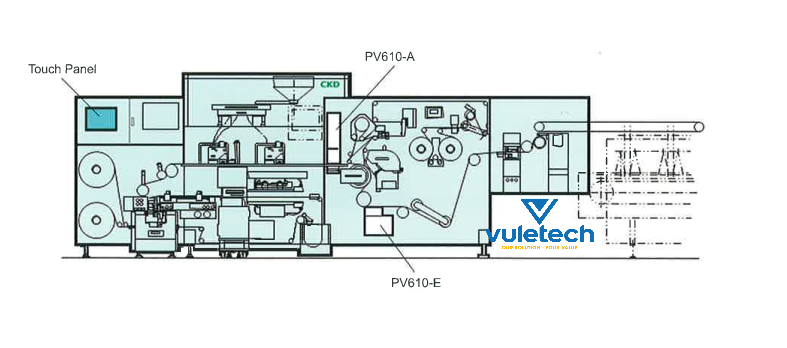

III. Structure of PharmVision PV610

1. External structure

FBP-600E-V Tablet Malformation Tester (CKD)

| Touch panel | W510 H353 D60 |

| Image processing equipment | W200 H177.8(U) D300 |

| Space required for test section | PV610-A (Top rail): W132 H557

D537(Bottom rail): W163 H124 D539 PV610-E (Bottom rail): W337 H349 D563 |

2. Technical parameters of PV610-A and PV610-E testers:

| Model | PharmVisisons PV610-A | PharmVisisons PV610-E |

| Describe | Before sealing: Shape/color of tablets (capsules) and foreign particles attached to tablets and sheets were detected. |

After sealing: Detected tablet shape (capsule) and foreign particles on the surface and front sheet of the tablet. |

| Test location | After inserting the tablets, before sealing | After sealing, before cutting |

| Tested object | Tablets (back), foil sheets | Tablets (front), foil sheet |

| Camera used | Color camera 5 megapixels | 5 megapixels . monochrome camera |

| Lighting method | Protective light with visible light Reflection with visible light | Reflected light with NIR light. Light reflected with visible light |

| Maximum functionality and detectability* | Check the tablets

1. Presence 2. Cut 3. Crack: ± 8% in difference area 4. Color difference Check the back of the tablet 1. Outer grain (black): 0.4mm sq. 2. Hair (black): 100μmxL3mm Check the leaf plate 1. Outer beads (color): 0.4mm sq. 2. Hair (black): 100μmxL3mm |

Check the tablets

1. Presence 2. Cut 3. Crack: ± 8% in difference area Check for tablet breakage 1. Outer grain (black): 0.4mm sq. 2. Hair (black): 100μmxL3mm Check the leaf plate 1. Outer beads (color): 0.4mm sq. 2. Hair (black): 100μmxL3mm |

* Function and maximum detectability may vary depending on product condition

Check the product:

High precision inspection from both sides of blister plate:

In addition to the usual pre-sealing inspection, post-sealing inspection has been established on the PharmVision PV610 product line

Inspect not only the back surface of the tablet but also the front surface of the tablet and foreign particles on the sealed surface immediately prior to sealing.

Furthermore, the use of a 5-megapixel resolution camera has provided outstanding detection accuracy at the highest level in the industry.

The bag blister surface is easy for the patient to see the abnormality.

Blister bag surface inspection can contribute to the reduction of claims in the market due to the presence of defective blister sheets

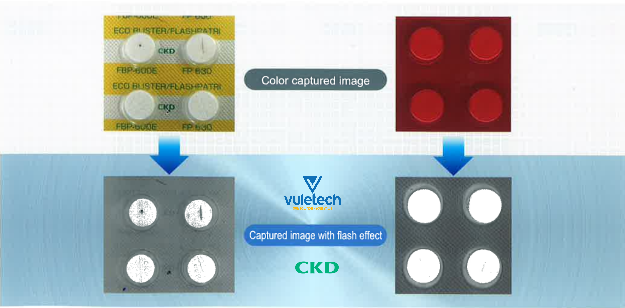

High spec / high resolution:

5 mega pixel high resolution camera provides outstanding performance in detecting small external particles

Flash function:

CKD’s unique technology of flash function allows printing to be erased and checked without affecting printing

IV. Benefits of using the Blister and Deformity Checker on Tablets

- Minimizing missed products

- Establish standards for rejecting defective products. (Remove personal standards of the inspectors)

- Reduce personnel costs for testing staff

V. Where can I buy a machine to check for blisters and abnormalities on tablets?

VULETECH chuyên cung cấp giải pháp về máy kiểm tra dị tật trên viên nén. Để biết thêm thông tin chi tiết, quý doanh nghiệp vui lòng liên hệ:

Vu Le Technology Co., Ltd

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com