Case Study: Implementing an Automatic Box Unpacking Machine – An Optimal Packaging Solution for Businesses

1. Introduction to Automatic Box Unpacking Machines

For over 17 years of partnering with manufacturing businesses, VULETECH has always been committed to providing optimal technological solutions, helping customers improve productivity, reduce costs, and modernize their production lines.

One of our recent successful projects is integrating an automatic box unpacking machine into a customer’s packaging line in the FMCG industry. This project not only improved operational efficiency but also created a significant step forward in factory automation.

2. Customer Challenges

Before project implementation, the customer faced several difficulties:

- High labor costs: at least two people were needed for the carton unpacking process.

- Limited productivity: only about 70 cartons per hour, insufficient to meet increased production demands.

- Manual errors: uneven carton unpacking, insecure sealing, affecting brand image.

- Incompatibility with existing production lines: production speed was hampered at the carton packing stage.

The customer set clear goals: reduce manpower, increase carton unpacking speed, and ensure stability and synchronization of the entire production line.

3. Vuletech Solution – Automatic Carton Unpacking Machine

After detailed survey and analysis, Vuletech proposed an automatic carton unpacking machine solution, optimally designed for modern factories.

Key features of the solution:

- Reduced operating personnel from 2 to 1 person.

- Superior carton unpacking speed: 300–500 cartons/hour.

- Stable and accurate: minimizes bending, warping, or missing adhesive errors.

- Compact design: easily integrated into existing factory space.

- Production line compatibility: operates synchronously with other packaging processes.

4. Achieved results

After implementing the Line Mespack automatic carton unpacking machine, the customer achieved significant results:

- Productivity increased 5–6 times compared to manual packaging.

- Labor cost savings: only 1 supervisor required.

- High stability: 100% standard cartons, no warping, and secure adhesive.

- Smooth production line operation: eliminates bottlenecks in production.

- Optimizing long-term costs: reducing material waste and minimizing rework errors.

5. Watch the video about the box unpacking machine:

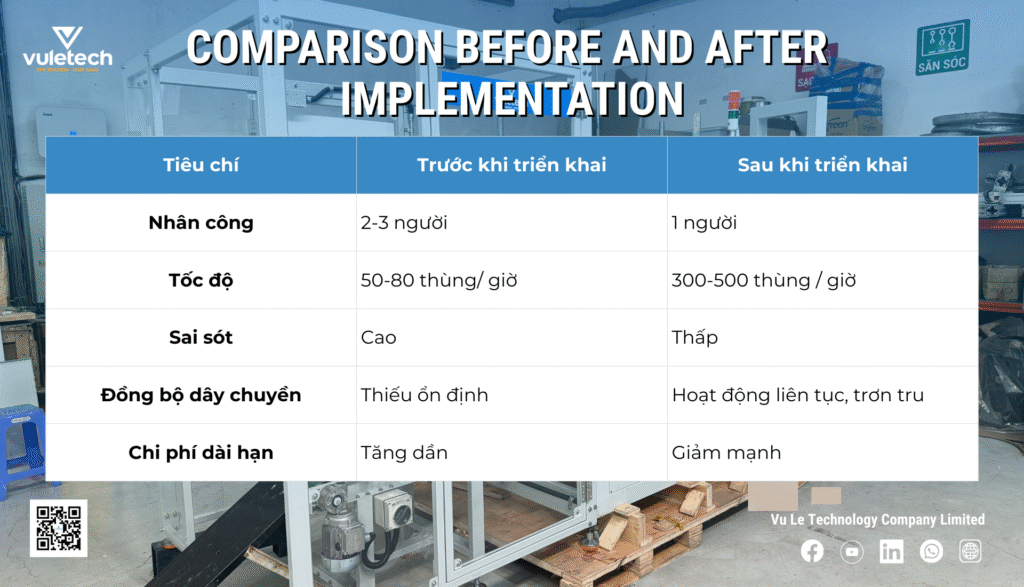

6. Comparison before and after implementation

7. Contact VULETECH for advice on carton unpacking machines:

The automatic carton unpacking machine project is clear evidence of Vuletech’s ability to provide smart and optimal packaging solutions.

With its modern design, superior speed, and flexible integration capabilities, this is the ideal solution for any business looking to improve productivity, reduce costs, and move towards complete automation.

Contact Vuletech today for advice, a solution demo, and a firsthand experience of the effectiveness of the Line Mespack automatic carton unpacking machine.

Vu Le Technology Co., Ltd. – specializing in industrial automation equipment, factory automation solutions, and robotics.

Address: No. 7, Lot C2, 659 Street, Phuoc Long B Residential Area, Phuoc Long Ward, Ho Chi Minh City, Vietnam

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com