I. Project Information:

- Industry: Fast-Moving Consumer Goods (FMCG)

- Location: Long Thanh – Dong Nai

- Application: Robotic Case Packer System for Laundry Detergent Products – Increased Efficiency, Reduced Workforce

II. Factory Situation:

Before automation, the process of packing laundry detergent bottles into cartons at the customer’s factory had many limitations:

- The product was packaged in large, heavy bottles weighing at least 3kg, requiring 5 workers to take turns lifting and packing, leading to fatigue and errors.

- Manual packing was uneven, affecting the final packaging speed of the production line.

- The need for increased production volume necessitated a faster, more stable, and safer solution.

III. Vuletech’s Robotic Case Packer Solution

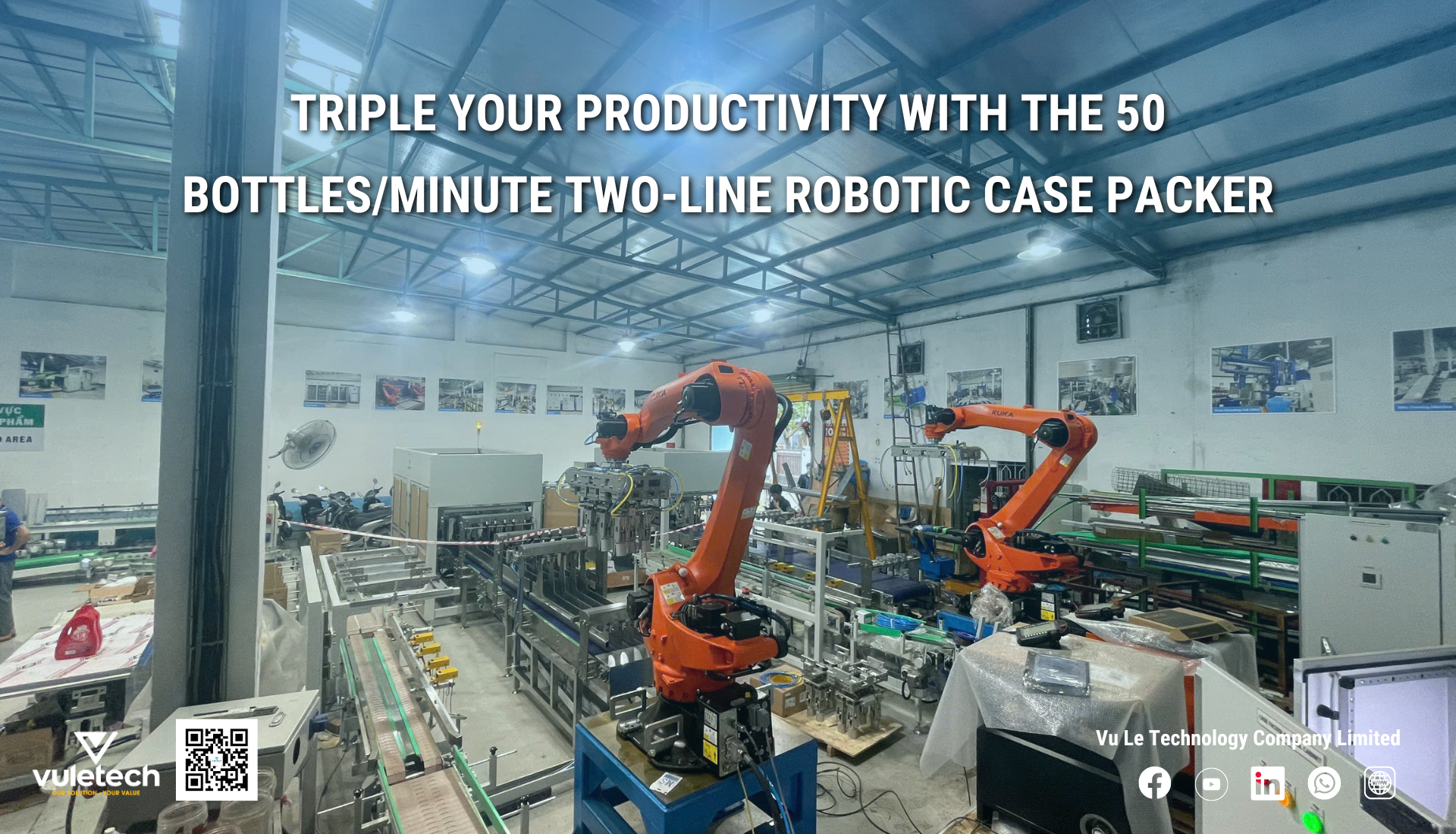

Vuletech implemented a Robotic Case Packer system using KUKA industrial robots, integrating sensors and specialized gripping mechanisms for laundry detergent products.

1. KUKA Robot with a payload capacity of up to 180 kg

Specialized in handling heavy products, suitable for the chemical and detergent industries.

2. Optimized Carton Stacking – Superior Performance

- Horizontal stacking solution of 3 cartons/cycle → optimizes time and reduces robot movement.

- Quick-change ribber design, easily adapts to product size.

3. Intelligent Recognition Mechanism using SICK Optical Sensors

- SICK optical sensors detect cartons and bottles at critical positions.

- Automatically adjusts the gripping position to ensure accuracy.

4. Superior Speed Compared to Manual Operation

- Two parallel lines, speeds up to 50 bottles/minute/line.

- Fully synchronized with parallel modules is the carton feeding system.

5. Safe Operation

- Light curtain in the robot’s operating area.

- Integrated safety door with Pizzato safety switch according to IEC standards.

IV. Results achieved

| Target | Before | After | Improvement |

|---|---|---|---|

| Workers stacking crates | 5 persons | 0 person | –100% direct labor |

| Stability | It depends on the human factor | High-precision robots | Absolute stability |

| Stacking speed | Shift changes | 50 bottles/minute/line | Increase by 250–300% |

| Sorting error rate | Occasionally, the container is misaligned. | nope | Improve packaging quality |

V. Value Proposition

- Optimized long-term labor costs.

- Improved quality, reduced returns due to incorrect carton stacking.

- Ensured safe operation according to IEC standards.

- Increased packaging productivity, suitable for expanding production.

VI. Contact VULETECH for advice on Robot Case Packers

Vu Le Technology Co., Ltd. – specializing in industrial automation equipment, factory automation solutions and robotics.

Address: No. 7, Lot C2, 659 Street, Phuoc Long B Ward, Thu Duc City, Ho Chi Minh City, Vietnam

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com