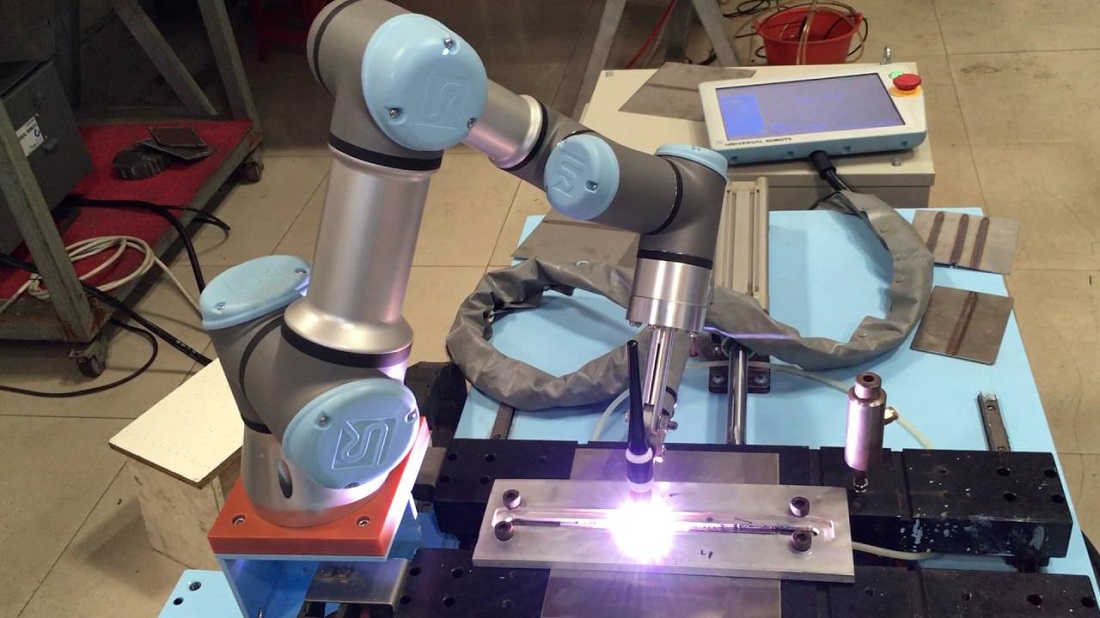

COOPERATIVE ROBOTS CAN BUILD PRODUCTION CAPACITY AND CAN KEEP HIGH QUALITY AND CONSISTENTLY OF WELDED PRODUCTS

REDUCES WASTE AND IMPROVES ACCURACY IN ELECTRICAL Arc Welding, VONFRAM Inert Gas Welding (TIG), LASER Welding, Inert Metallic Gas (MIG) Welding, ULTRASONIC AND PLASMA Welding

Collaborative robots can increase flexibility, efficiency, and take your mind off welding tasks. The robot can be easily moved to the places where you need help implementing the application. When the task is complete, you can repurpose and redeploy the robot to other areas of the production process. The collaborative robot can handle electric arc welding, TIG welding, laser welding, MIG welding, ultrasonic welding, plasma welding, spot welding as well as brazing and brazing. With versatility and flexibility, collaborative robots are suitable for many tasks, increasing operational efficiency for production lines, helping your business receive more orders.

Improve workplace safety by allowing robots to handle dangerous tasks. If the robot comes into contact with a person, our patented technology limits the force of contact. The user can also program the UR robot to slow down when someone enters the robot’s work area and continue operating at full speed when the person leaves.

Weld

- Many types of welding can be performed with the UR robot, such as TIG welding, MIG welding, spot welding, electronic rod welding, ultrasonic and plasma welding. Reduced production downtime and less material waste are among the advantages of implementing a collaborative robot arm.