Industrial PC IPC for all applications

Along with associated software, PCs in various shapes and forms are at the core of a diverse range of automation activities such as machine control, manufacturing processes or logistics systems, connectivity network of system components, data acquisition or image processing. For control operations, PC-based control technology offers great scalability and flexibility and is therefore increasingly widely used in place of hardware PLCs.

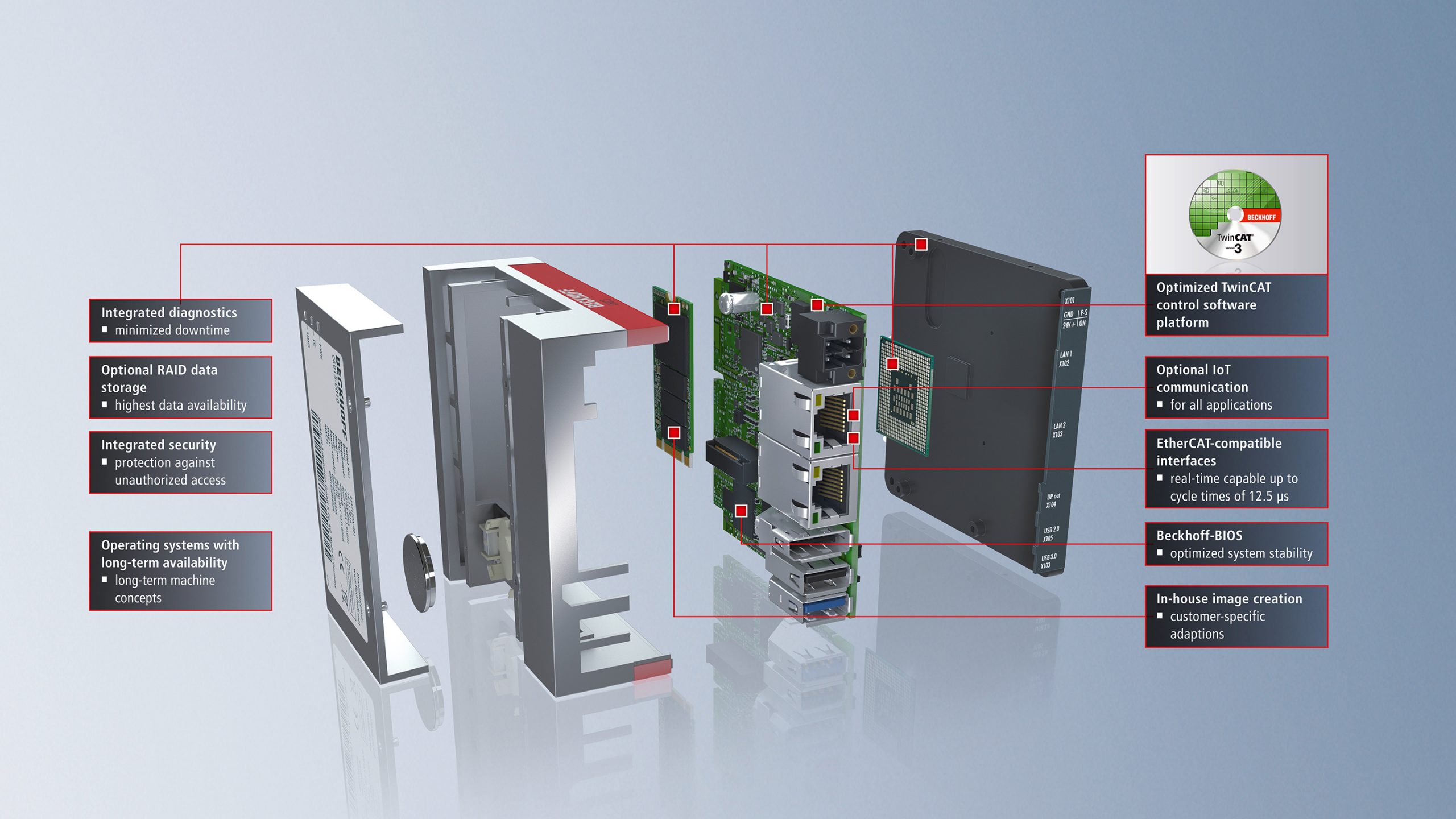

Beckhoff was one of the pioneers of PC-based automation: the first PC control system was delivered in early 1986. Beckhoff industrial PCs have been integrated by many new technologies in recent years. . Combined with TwinCAT automation software, provides a high performance control system for PLC, NC and CNC functions.

A key feature of Beckhoff products is the use of advanced, high-performance microprocessors and components for the development and design of Industrial Computers: integrating the latest developments offered by the technology market level and is used successfully all over the world.

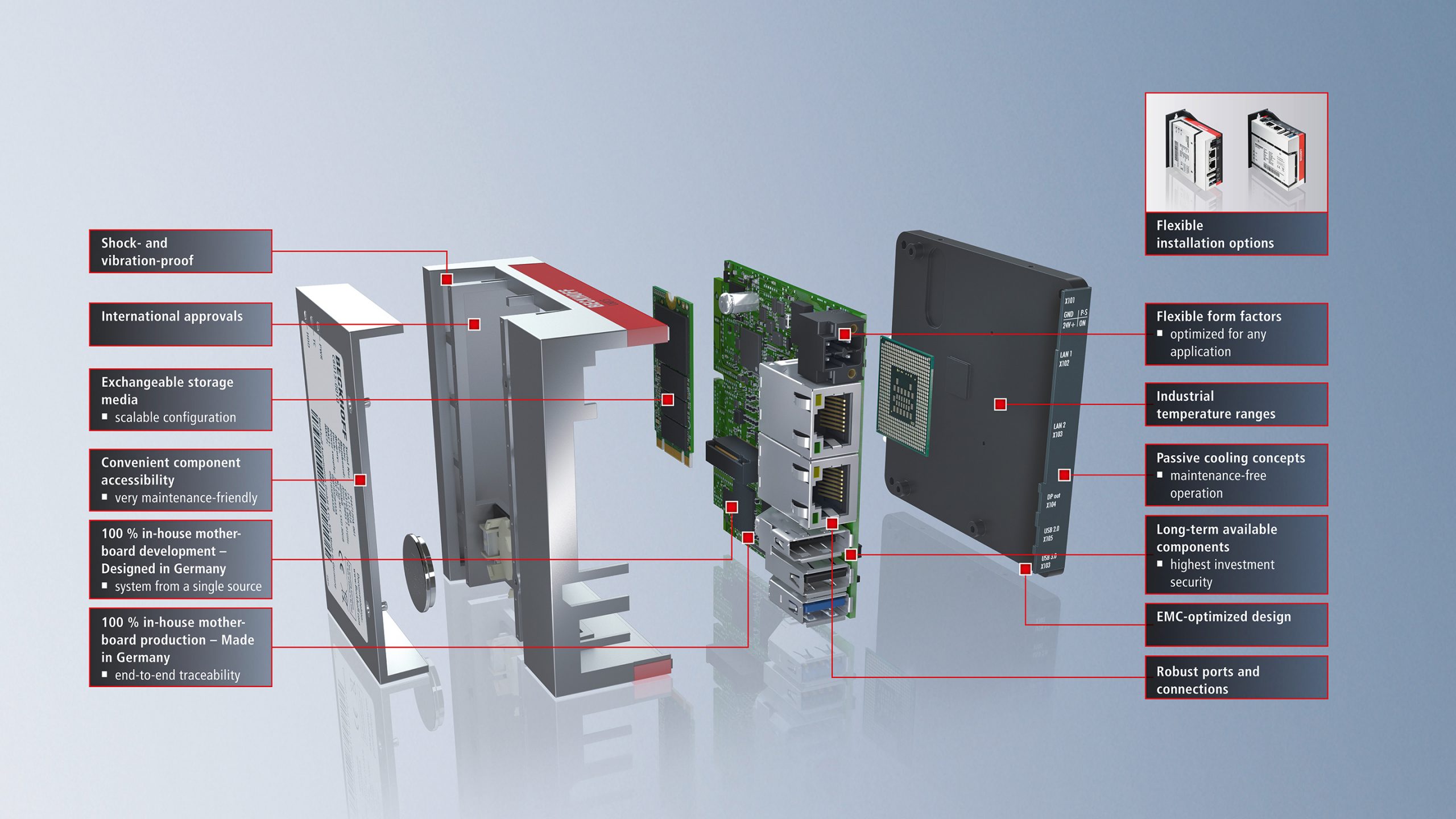

Core Advantage: Beckhoff Industrial Computer

Highly scalable catalog:

Beckhoff offers a highly scalable portfolio of Industrial Computers, from single-core to multi-core and multi-core with all types of interfaces, screen sizes, form factors with different or identical CPUs identical and with different layers of protection.

Standard industrial computer with variable configuration:

Almost no application is exactly the same, and so are most of Beckhoff’s standard industrial computers. The configuration flexibility of industrial computers allows users to choose exactly the device that best suits specific applications. With processors from Intel ® Celeron ® to Core™ i7 , different RAM and memory options, various operating systems and TwinCAT generations – the options menu is huge, resulting in virtually unlimited Standard industrial computer models:

- Flexible form factors

- Scalable CPU architecture: ARM, x86

- Sorage media versatility: HDD, SSD, CFast, μSD

- Wide range of interface types and screen sizes for all protection classes and installation requirements

- Custom models for mechanics, electrical and electronic components, software and design

- Integrate industry specific functions

- Tailored to specific applications and company design guidelines

- Features and designs specific to each customer’s requirements

Beckhoff Industrial Computers can be designed and engineered for each customer’s specific requirements. The range of options is extensive and ranges from company logos or special labels and personalized functions to Industrial Calculators built to perfectly match the client’s corporate design.

Over 30 years of expertise built into every industrial computer:

Beckhoff is one of the pioneers of PC-based automation: Beckhoff has been developing the principle of using PC-based control technology for automated processes as early as 1986.

Because of this and the close relationship between Beckhoff and global IT innovators like Microsoft and Intel, users of Beckhoff IPCs will always enjoy a technological edge.

Hardware: Internal performance test:

At Beckhoff, the chain of seamless integration begins with in-house production of the motherboard and ends with rigorous in-house testing to confirm the performance of the hardware that interacts with the TwinCAT control software. Users can count on the long-term availability of the product and a complete system that is optimally coordinated.

Best software for hardware Beckhoff:

High-performance hardware needs capable software to match. With the company’s own BIOS development, Beckhoff is able to offer fully customized software packages. The same applies to Windows operating system imaging development and Industrial Computer diagnostics for standardized access to all Industrial Computer information. The in-house software development also ensures the system’s real-time capability to perform TwinCAT real-time tests and even more precisely tune the Industrial Computer software to the hardware.

Superior technology:

The unmistakable design and high quality of the Beckhoff Industrial Computer were fixed parameters in the product development process from the outset.

Starting with the selection of materials, engineers ensure that superior technological standards are reflected in the attractive design, high-quality construction and surface finish of each product.

The end result is a consistent, modern user experience. The Panel’s housings are prime examples, cast from a solid block of aluminum. We manufacture shells this way because:

- Beckhoff wanted the premium design philosophy to be clear and visible to the end customer

- At the same time increase the value of machines and systems.

In many cases, the Tablet or Control Panel serves as a user interface with high recognition value.

Available globally:

With a well-invested component inventory, Beckhoff can ensure long-term availability across the entire product portfolio:

- Total is five years for industrial PC

- Ten years in total for embedded PC

End customers will always have peace of mind knowing that the product will be supported for the long term: through hardware updates with easy CPU integration in the same form factor, reducing hardware imaging and training costs. software, as well as quick customer service response times. In addition to standard availability, serviceability is assured for years to come thanks to a foresight component stockpile.

Fast delivery performance:

By keeping up to six months’ worth of raw materials and components in stock, Beckhoff is able to supply even when global market conditions become difficult.

Beckhoff’s worldwide presence in more than 75 countries ensures prompt service and support to clients operating globally in the local language. Furthermore, geographical proximity helps develop a deep understanding of the technical challenges facing customers around the world.