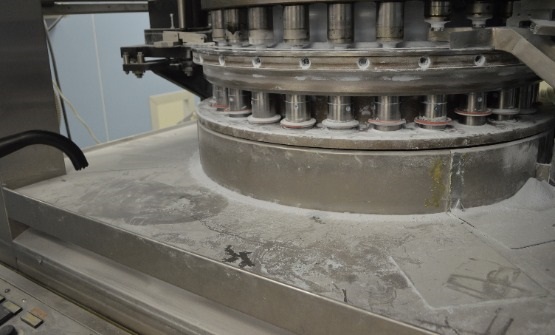

Manufacturers in the Chemical-Pharmaceutical industry must always ensure the highest level of product quality. With the above requirements, contamination is a great danger to the quality of the product and violations of GMP standards can occur.

There are three types of contamination:

– Physical contamination: debris or dust from machinery and equipment.

– Chemical contamination: steam, moisture

– Biological contamination: bacteria, fungi, viruses.

GMP is a system of good manufacturing practice standards to control factors that can affect the process of forming product quality, in order to ensure the best quality products. Equipment such as industrial vacuum cleaners must have a HEPA filter. For optimum efficiency, the machine is often installed on production lines or in workshops. On the other hand, Delfin’s pneumatic feeding system also ensures that products are transported safely, avoiding contact with contaminated bacteria for the best quality final product.

INDUSTRIAL VACUUM VACUUM SOLUTION USING HEPA FILTER FOR THE CHEMICAL-PHARMACEUTICAL INDUSTRY

Benefit:

– Maintain the highest level of hygiene in the work area (Floor, machinery, tools) by preventing the generation of dirt.

– Removal of dust at the source in the production process.

– Removes the risk of product contamination in the production process.

With a design of stainless steel, a variety of HEPA filters, smooth surfaces for easy cleaning… Delfin offers the best solutions for the Chemical-Pharmaceutical industry.

OPTIMIZED SOLUTIONS FOR CHEMICAL-PHARMACEUTICAL INDUSTRY

Three-phase industrial vacuum cleaner, the ideal solution for the Chemical-Pharmaceutical industry. The filter has a large cross-section and is designed to prevent the accumulation of dust, making maintenance safe and easy for the user.

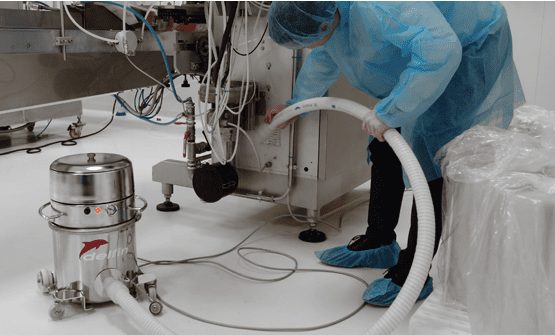

CLEAN ROOM vacuum cleaner ONLY

Possible sources of contamination in cleanrooms from:

– Clean room architecture

– People and clothes

– Product

– Equipment used in clean room

Therefore, each device used in a clean room environment must comply with the relevant ISO standards as well as features and special design to make maintenance easier.

Delfin has designed the special product line LabControl to ensure cleaning efficiency and compliance with ISO standards.

SUPPLY SYSTEM FOR CHEMICAL-PHARMACEUTICAL INDUSTRY

For the Chemical-Pharmaceutical industry, transportation of materials (Powder, granules, solids) is a very sophisticated step that has an important influence on product quality in the production process. Therefore, using a closed feed system eliminates the risk of contamination, ensuring quality and production efficiency.

DELFIN FEEDING SYSTEM

Delfin has developed feeding systems to meet any customer’s material transportation needs in the Chemical-Pharmaceutical industry.