Maintenance and cleaning of machine tools and the working environment are very important activities for the metalworking industry, in order to limit machine downtime, ensure productivity and safety in production.

MAINTENANCE OF MACHINE TOOLS: HANDLING OIL AND METAL FACES

In the production process, industrial machinery produces a large amount of iron filings and poses the risk of reducing productivity and product quality. The Tecnoil product line was therefore designed to solve this problem. Advantages:

– Direct handling oil and metal shavings on production machinery

– Reuse oil, save cost

– Easy maintenance and cleaning of industrial machinery

– Reduce the number of machine downtime for maintenance

Delfin’s Tecnoil’ series is a highly finished industrial solution. that can handle oil and iron filings easily without clogging due to thick dust.

BEST VACUUM SOLUTION FOR OIL USED UTILITIES

The presence of metal shavings inside the oil tank after the process makes it difficult to filter and reuse the emulsion after each duty cycle. With the use of an industrial vacuum cleaner, it is possible to vacuum oil and chip mixtures from any type of tank, small or large, separating the oils from the chips and allowing the emulsions to be reused for the cleaning cycle. job

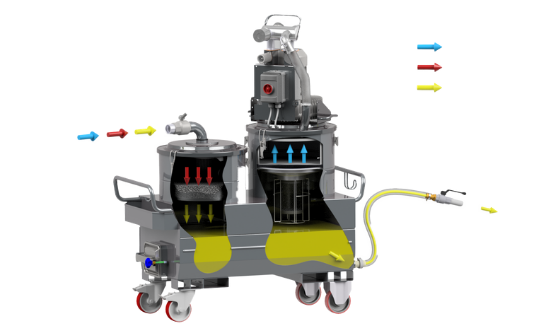

HOW TECNOIL WORKS

Oil and swarf are vacuumed and enter the filter chamber of the vacuum cleaner, then the swarf is filtered and retained by the grill basket allowing for an easy collection. The filter and float prevent oil or oil mist from coming into contact with the engine and causing significant damage to the vacuum cleaner.

The oils are then collected in the container and returned to the cnc machine by means of a discharge pump, which ensures savings on oil acquisition.

VACUUM MACHINE FOR 3D PRINTING INDUSTRY EASY

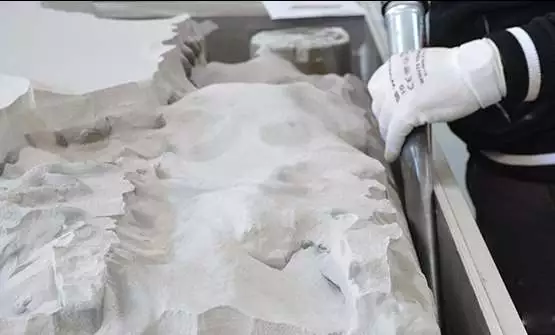

In the 3D printing industry, the production process generates dust with a high risk of explosion, such as titanium dust, aluminum dust or carbon dust. Therefore, when production is complete, factories must use industrial vacuums to remove dust and treat residual dust to:

– Avoid product contamination

– Make sure that the dust has been handled safely

INDUSTRIAL VACUUM MACHINE HANDLING PREMIUM METHODS

The dust particles generated during the extraction of precious metals have great economic value. Therefore, Delfin offers a dust extraction solution to recover all dust particles generated during the production process, in order to maximize the value of the resource.

EXPLOSION RESISTANT INDUSTRIAL VACUUM VACUUM ATEX CERTIFICATE

The solution is designed through the use of inert oil to safely handle flammable and explosive dust, reducing the risk of fire and explosion during operation.

Delfin’s solution is ATEX certified for explosion prevention, integrated with a centrifugal dust separator, minimizing dust generated in the production process.