Applications that determine the location and presence of the lid

A missing or misaligned cap in the product package can lead to unnecessary product waste and costly rework, resulting in lost profits. Our system can quickly identify products with missing or improperly fitted caps, remove them from the production line, and alert operators to the problem.

Fill level detection

Unnecessary product waste is the cause of lost profits, and underfilled products can lead to trouble from government regulators. Along with determining the position and presence of the cap, our visual inspection system is also capable of performing fill level checks to ensure that all packages are properly filled.

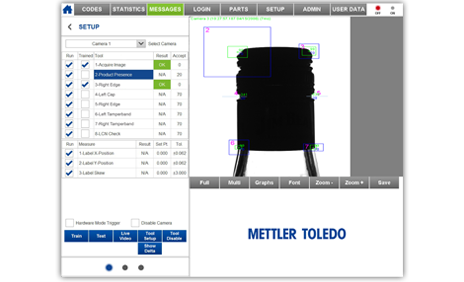

Smart camera and computer based visual inspection system

Simple cap detection applications and tamper-proof sealing checks can be handled quickly and easily with a smart camera-based system, but depending on the number of other checks desired, there are Additional processing power may be required to maintain production rates. In that case, the computer-based test system can accelerate to high capacity without loss of accuracy.