Collaborative robots (cobots) are becoming a “powerful” arm and a very effective solution in the global “war against COVID-19”. In this article, we will explore the use of robots (specifically Universal Robots – UR’s collaborative robots) during the pandemic, as well as some other contributions in meeting the need for disinfection and review. COVID-19 testing worldwide.

COOPERATIVE ROBOT DISINFECTION

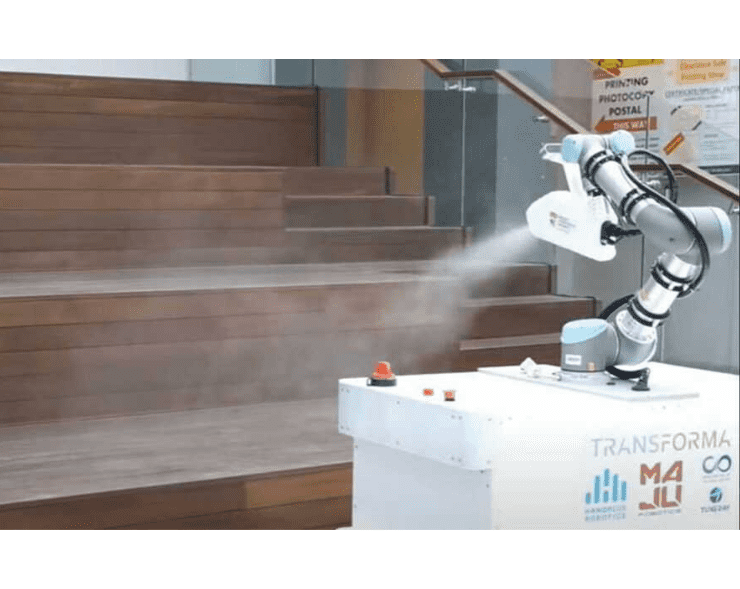

The global pandemic has led to a huge demand for effective deep cleaning and disinfection technology that avoids direct human contact with areas at risk of infection. In April, researchers from Nanyang Technological University (NTU) released a solution to this problem called eXtremeDisinfection roBOT (XDBOT). This robot is composed of a UR5 robot arm with an electrostatic nozzle, placed on a movable stand.

The researchers programmed the robotic arm to accurately mimic human hand movements, thus being able to clean hard-to-reach surfaces such as under beds or under tables – something disinfecting robots transmit system can’t do it due to the lower level of dexterity. This system includes a nozzle and a large 8.5 liter tank containing disinfectant solution, allowing XDBOT to quickly spray disinfectant over a large area while ensuring deep cleaning effect.

Another important feature is that XDBOT is capable of semi-automatic operation. This allows humans to control the robot remotely via a tablet or laptop, thereby limiting direct contact with potentially infectious surfaces.

With the ability to operate continuously for four hours on a single charge, XDBOT has been successfully tested in public areas on campus. The team is currently preparing to test the technology in public hospitals.

Also in April, a team at the University of Southern California (USC) released a prototype of the Agile Dexterous Autonomous Mobile Manipulation System-UV (ADAMMS-UV). Like XDBOT, ADAMMS-UV is composed of a UR5 robotic arm placed on a movable stand. However, instead of spraying disinfectant, ADAMMS-UV uses a UV lamp capable of breaking the DNA structure of the virus, mounted on the base.

Equipped with grips provided by partners, ADAMMS-UV is capable of grasping objects, as well as cleaning hard-to-reach surfaces. Like XDBOT, ADAMMS-UV can be operated remotely while ensuring compliance with regulations on social distancing and infection prevention. This collaborative robot is equipped with cameras for easy control by the operator. In addition, a time-of-flight (ToF) sensor camera is also equipped on the robotic gripper that scans the surrounding area and emits infrared light to determine the depth of field. Based on this information in the form of images, ADAMMS-UV is able to build a 3D model of the area to be disinfected.

Satyandra Gupta, Director of the Advanced Manufacturing Center at USC, said: “We initially developed a mobile collaborative robot application as a Machine tending solution to assist humans in manufacturing operations. When the COVID-19 pandemic broke out, USC was forced to clean its labs, we chose the cobot UR5 because of the built-in safety feature, which means we could still use the robot. This collaboration is in the direction of collaborating with people. UR is a leader in cobots, so it was an easy decision for us.” Mr. Gupta added: “The cleaning and disinfection inside the laboratory is very complicated. You can’t just spray a room with disinfectant. Therefore, we studied UV sterilization and found this to be a viable option. However, the solutions on the market at that time were more about disinfecting rooms on a large scale, for example, not being able to open drawers, take things out, put objects on tables, and put UV sticks on things. objects for sterilization”. Currently, his team is working on an option to add a collaborative robot UR5 to double the operation and sterilization speed of ADAMMS – for example, a robotic arm that can open drawers while the arm is The rest can hold a UV lamp.

The team has successfully tested the prototype in the laboratory and is in the process of further validation to ensure the technology can be applied to public buildings such as hospitals, hotels or offices.

TESTING FOR COVID-19 WITH COOPERATE ROBOT

COVID-19 has also created the biggest demand for testing ever, and this is an area where robotics can be fully utilized. To meet this surge in demand, Esben Østergaard, co-founder of UR, unleashed his creativity to design and develop the world’s first throat sampling robot. This is a product launched by Lifeline Robotics, which he co-founded with the Maersk Mc-Kinney Moller Institute at the University of Southern Denmark (SDU).

Through cooperation with robotics researchers at SDU, the robot was developed as a UR3 robotic arm with a customized 3D printed end-effector. The process is very simple. First, the patient scans his or her identification card. Immediately after, the robot will prepare a test kit, which includes a labeled sample vial with the patient’s identification number, and take a cotton swab. With its built-in vision system, the robot is capable of identifying precise sampling strokes from the patient’s throat. As soon as the sampling step is completed, the robot arm will place the sample in the vial and screw the cap tightly closed. The vial will then be sent to a laboratory for analysis. The whole process takes about 7 minutes, of which taking a sample from the patient’s throat takes only 25 seconds. The system was officially launched in Denmark at the end of May.

Also at the end of May, DetectaChem – a company that manufactures handheld detection devices based in Houston, Texas, launched a unique COVID-19 testing solution on the phone platform. This is a low-cost at-home COVID-19 testing solution that returns results to patients via smartphone in just 15-30 minutes. This unit has deployed three UR10 cobots with the function of removing the plastic film covering the test kit placed on the turntable, helping to quickly maximize the production scale of the COVID-19 test product. The product is awaiting approval from the US Food and Drug Administration (FDA).

AND MORE!

One of the many ‘benefits’ of robots, specifically the UR collaborative robot, is the flexibility in supporting development and automation quickly. This is a really necessary feature in a time of crisis like today. This past March, for example, the Spanish carmaker SEAT decided to convert one of its car production lines into a ventilator production line. The automotive giant installed a robotic arm UR10e at the end of the line with a quality check function that locks the ventilator control box.

Also in Spain, the plastic manufacturing company Pepri began to produce plastic components for hospital beds to meet the increased demand in the context of the pandemic. Leveraging on the rapid redeployment of the UR cobot, Pepri quickly moved into manufacturing plastic bedside rails, headboards and footboards. The UR collaborative robot is used to cut blow-molded plastic parts.

The contribution of robotics technology advancements in meeting the spike in demand caused by the COVID-19 pandemic is encouraging. Collaborative robots have made a difference to people’s lives by performing tasks that pose health risks and ensure human safety.

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

Follow VULETECH at:

► Website: https://vuletech.com/

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw

Nguồn: UR