Every business in the market has certain vulnerabilities, big or small, that will directly affect the business. In production Downtime is considered as one of the dilemmas that almost every business encounters. To make it easier to imagine, you can imagine that each factory will lose 5% of its productivity, with experience losing up to 20% due to Downtime. A single manufacturer’s bottom line can include up to 800 hours of downtime, resulting in millions of dollars in lost revenue. Minimizing downtime in production is just as important as maximizing quality and output to maintain profitable contribution. To learn more about what Downtime is, don’t skip this article.

I. WHAT IS DOWNTIME?

Downtime in production is divided into two different categories: planned and unplanned. Planned downtime and budget stops during production such as scheduled maintenance and product changes. Unplanned downtime in production occurs when equipment that is slated to operate has an unexpected event such as when equipment failure or out of material occurs.

While all Downtime comes with its price, it’s important for manufacturers to service their machines as a form of precaution to reduce the chance of unplanned downtime, a costly process. much more.

II. CAUSE OF DOWNTIME

1. In the production plan.

Scheduled machine maintenance is an example of predictable production downtime. Accordingly, workers will carry out maintenance activities and maintenance of details and equipment to ensure that there are no problems when the production line is in operation.

Besides, product switching is another example of planned downtime. Product changeover is the process that occurs when a factory changes the production of one product to another as planned.

2. Beyond the production plan

Unplanned downtime is any problem that arises while production is in progress. These issues are often beyond the plant’s ability to anticipate and include:

Machine and equipment malfunction: This can happen when machinery and equipment fail to have parts such as sensors and motors, leading to replacement or repair.

Network problems: In today’s connectivity environment, factory operations may be halted due to internet problems;

Inadequate Maintenance: Unplanned downtime can arise when machinery is not properly maintained or inspected. This not only increases machine downtime and prolonged downtime, but also creates an unsafe environment for floor workers.

III. DOWNTIME IMPACTS ON BUSINESS

Once we have a clear understanding of what downtime is, we should now focus on the trouble they cause from the true cost of downtime (also known as TDC), including analysis of all the factors involved. costs associated with downtime. The two variables of TDC are tangible cost and intangible cost.

1. Tangible costs:

- Reduced production: Each product a manufacturer produces represents some amount of potential profit. The value that the factory creates will accumulate over time based on the rate of production per unit.

- Reduced capacity: Stopping production causes plant capacity to be suboptimal. This becomes serious if the market demand or orders spike.

- Direct Labor: When there is a shutdown in production, production levels will drop to the maximum low while your labor remains the same. This increases the actual cost of the plant.

- Inventory: Downtime causes the factory to store inventory. Meanwhile, the cost of holding inventory is usually around 10%-30% of the inventory value per year, a huge percentage.

2. Intangible costs

- Responsiveness: When downtime occurs, employees must focus on solving problems in the plant. Besides, the factory cannot produce finished products… this makes meeting the delivery schedule a difficult problem/

- Stress: Downtime can put a lot of stress on both employees and the machines they are operating. When a system goes down, it overloads employees with work when it comes back up. On the other hand, if a machine needs to produce at full capacity (compensating for downtime) for long periods of time, they are more likely to malfunction.

See also: i-MAG . intelligent factory management software

IV. HOW TO REDUCE DOWNTIME IN PRODUCTION

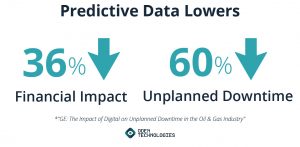

A GE study of the oil and gas industry found that only 24% of participating global operators described their maintenance strategy as “predictive”, or an approach based on collection and management. data and analysis efficiently and effectively. The most common strategies used by study participants are the reactive approach or the planned approach.

Regarding the unplanned downtime associated with each approach:

- The response strategy averaged 8.43% during Downtime in addition to the annual plan.

- Planned strategies average 7.96% during Downtime in addition to the annual plan.

- The strategy predicts an average of 5.42% during annual unplanned downtime.

Combined with the additional costs of repair, labor, transportation, and equipment, the reactive and planned approaches result in a revenue hemorrhage of just $60 million per year. A predictive data monitoring approach cuts those losses by almost 40%. These numbers show the truth about the power of predictive and analytics data to dramatically reduce the Downtime that a manufacturing plant can see.