3-Axis Vibration Sensors

High-performance 3-Axis Vibration Monitoring helps catch failures earlier, reduce downtime, and simplify predictive maintenance with precise, real-time diagnostics so teams can act before problems escalate. High-resolution 3-axis sensing more accurately detects issues like imbalance, looseness, or misalignment, helping teams prevent unexpected breakdowns and costly repairs. Available in both line-powered and battery-powered models, this technology easily gathers and delivers vibration data no matter where the equipment is located.

- 3-axis sensing: Capture a complete picture of machine health

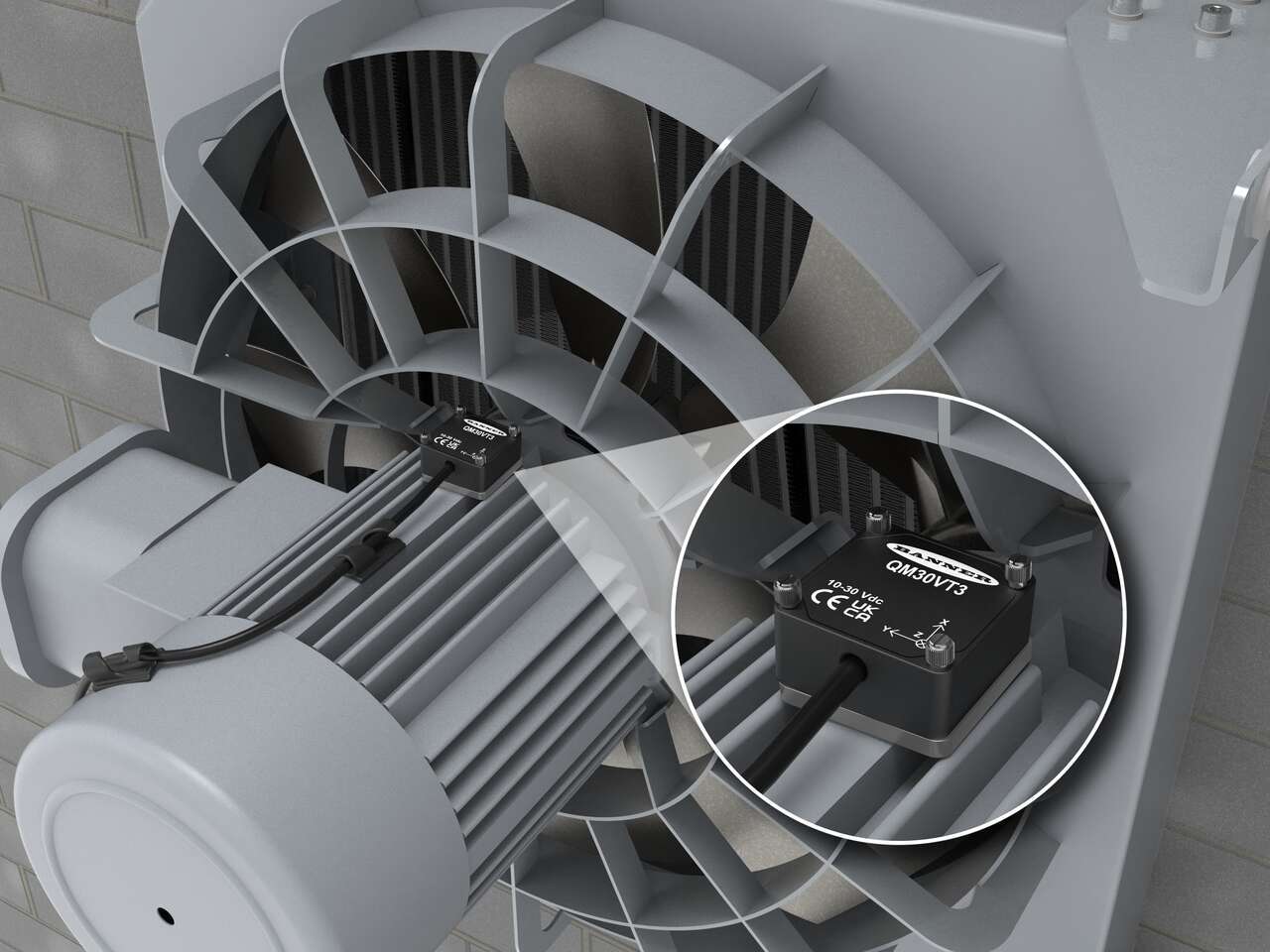

- QM30VT3 sensor: Sensor processes data onboard, simplifying integration into Modbus networks

- Q45VA3C multihop radio: All-in-one device combines sensor, radio, and battery power in a rugged IP67 housing and installs easily using magnetic or epoxy mounts; the go-to solution for most rotating equipment

- Q45VT3 multihop radio: Battery-powered radio connects to QM30VT3 sensor (sold separately), allowing sensor mounting on the motor or other equipment and remotely locating the radio when space is constrained

- VIBE-IQ: QM30VT3 sensors have built-in predictive maintenance—no expertise required

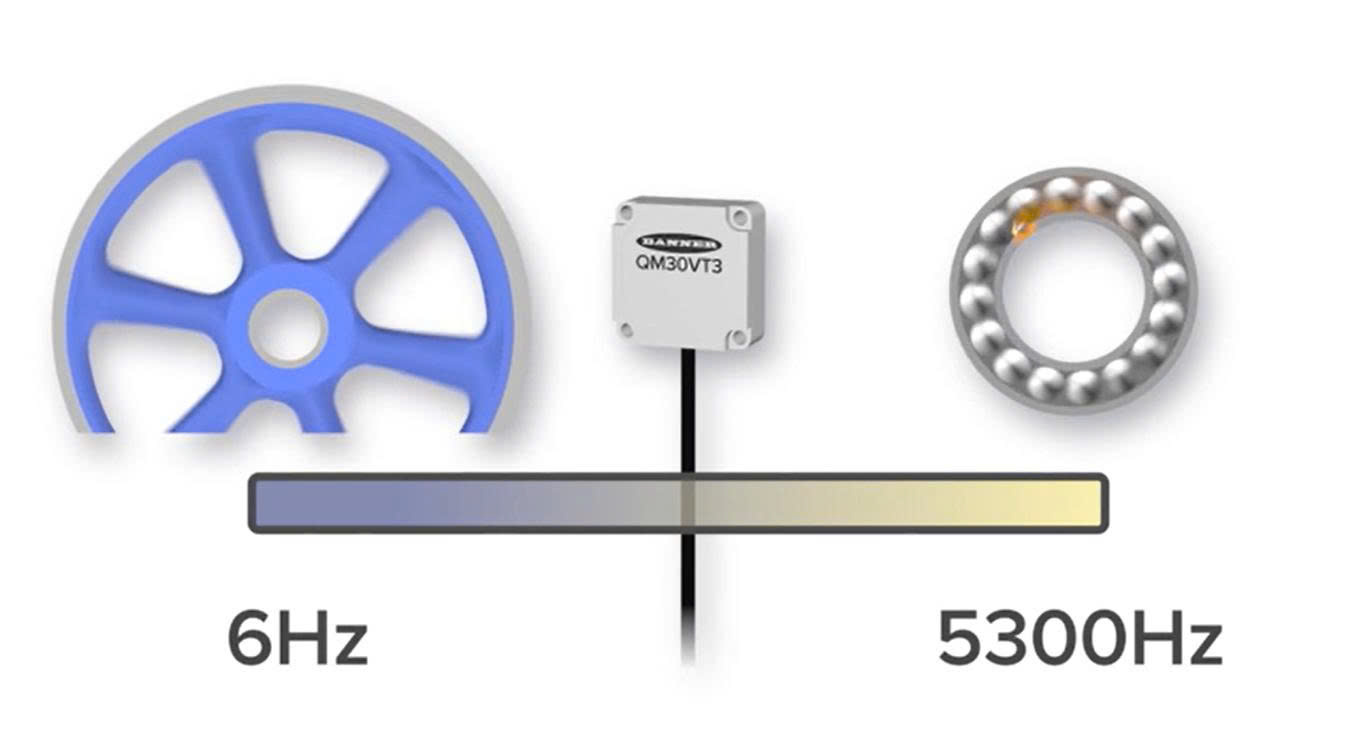

- Wide frequency range: Monitor a full range of equipment and fault types with 6–5300 Hz detection

- High-speed sampling: Prevent downtime in high-speed devices

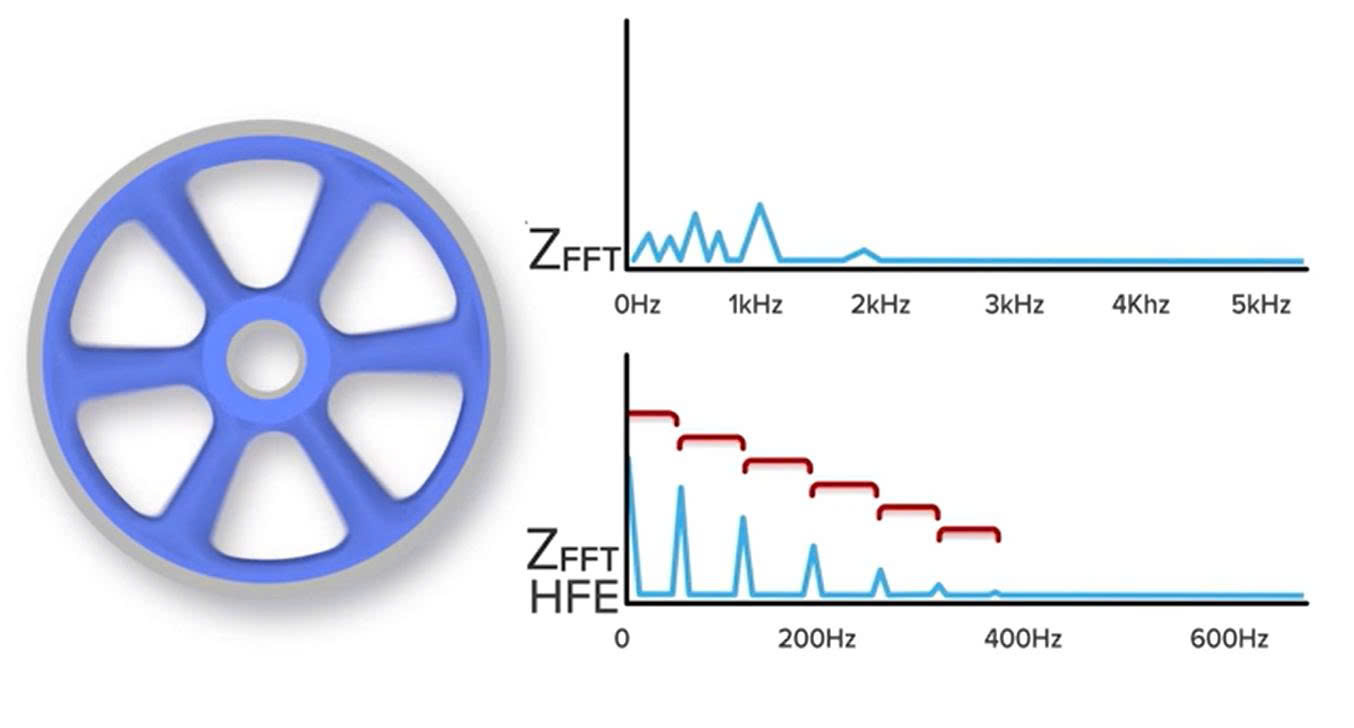

- FMax: Fine-tune resolution to catch faults on both high- and low-speed machinery

- HFE: Filter out low-frequency noise to isolate and detect early-stage bearing and lubrication issues

FEATURES

BENEFITS

Built-In Predictive Maintenance—No Expertise Required

With VIBE-IQ built into line-powered QM30VT3 sensors, machine learning detects vibration baselines and automatically generates warning and alarm thresholds so anyone can monitor assets—no gateway or expertise required.

Monitor a Full Range of Equipment and Fault Types with 6–5300 Hz Detection

Detect early-stage fault symptoms in motors, gearboxes, and other equipment before failures escalate. From imbalances and misalignment to bearing wear and gear meshing, the 6 Hz to 5.3 kHz frequency range covers both low-speed and high-speed assets.

Prevent Downtime in Slow-Rotating Assets

Capture detailed low-frequency vibration data and short-duration impact events—like early-stage bearing faults—from slow rotating assets using a high-speed 26.8 kHz sample rate for clear resolution of high-frequency transients.

Focus Monitoring Where It’s Needed with Adjustable Frequency and Resolution

Adjustable Frequency Max (FMax) lets users tailor the frequency range and sample length to machine speed and fault characteristics. Higher FMax captures a broad frequency range, using shorter sample times and default resolution suitable for detecting faults in high-speed assets. Lower FMax values provide progressively finer sample resolution and longer sampling times for detecting faults in very slow-moving assets

Detect Early Signs of Bearing and Race Wear in Slow-Moving Equipment

High-Frequency Enveloping mode (HFE) isolates high-frequency signals by filtering out low frequencies, making it easier to detect early-stage faults like bearing wear and lubrication issues. Combining HFE with a lower FMax setting extends sampling time and improves resolution while isolating high frequencies, which is critical for detecting weak high-frequency fault signatures in slow-speed assets otherwise masked by dominant low-frequency vibrations.

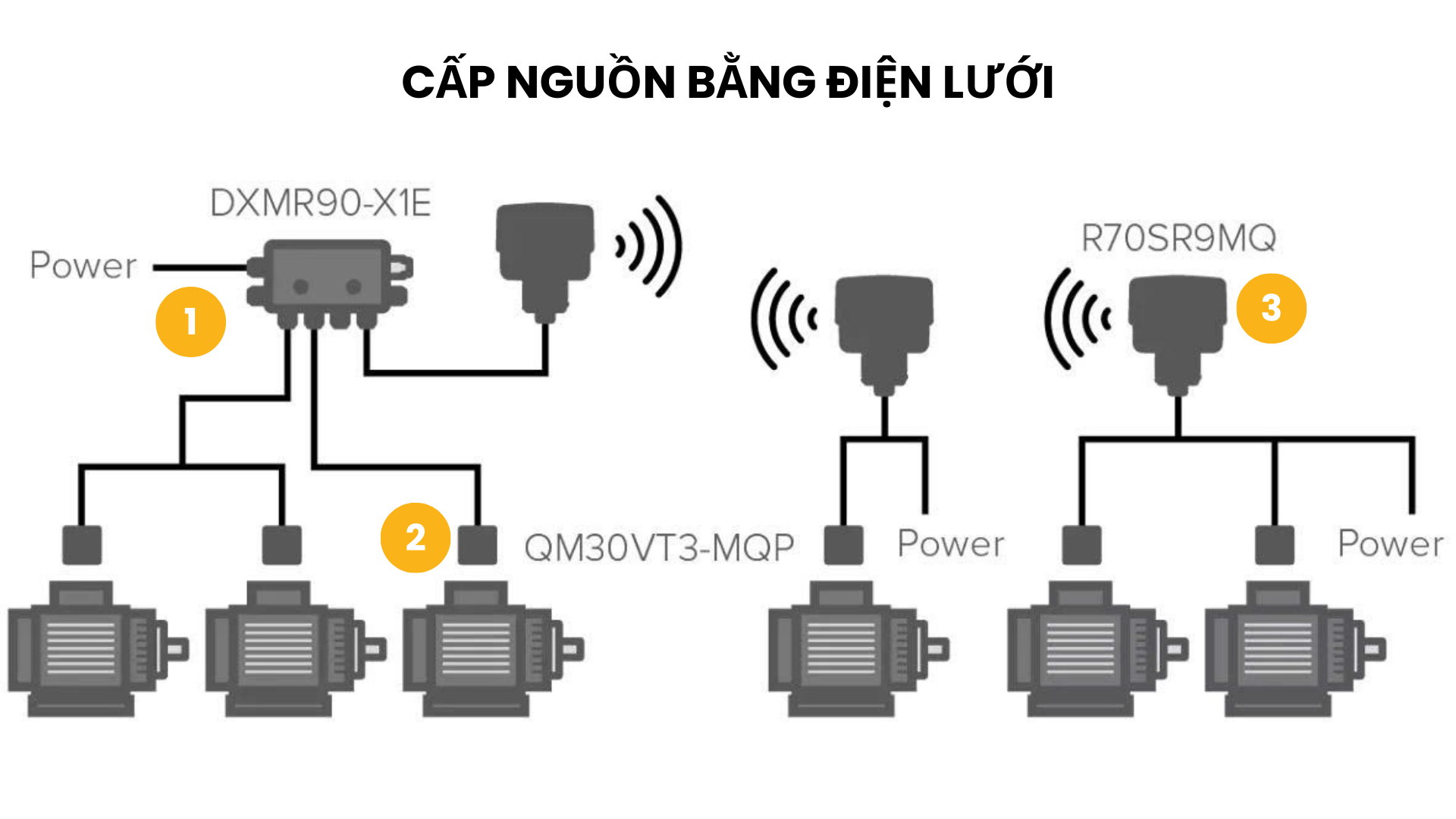

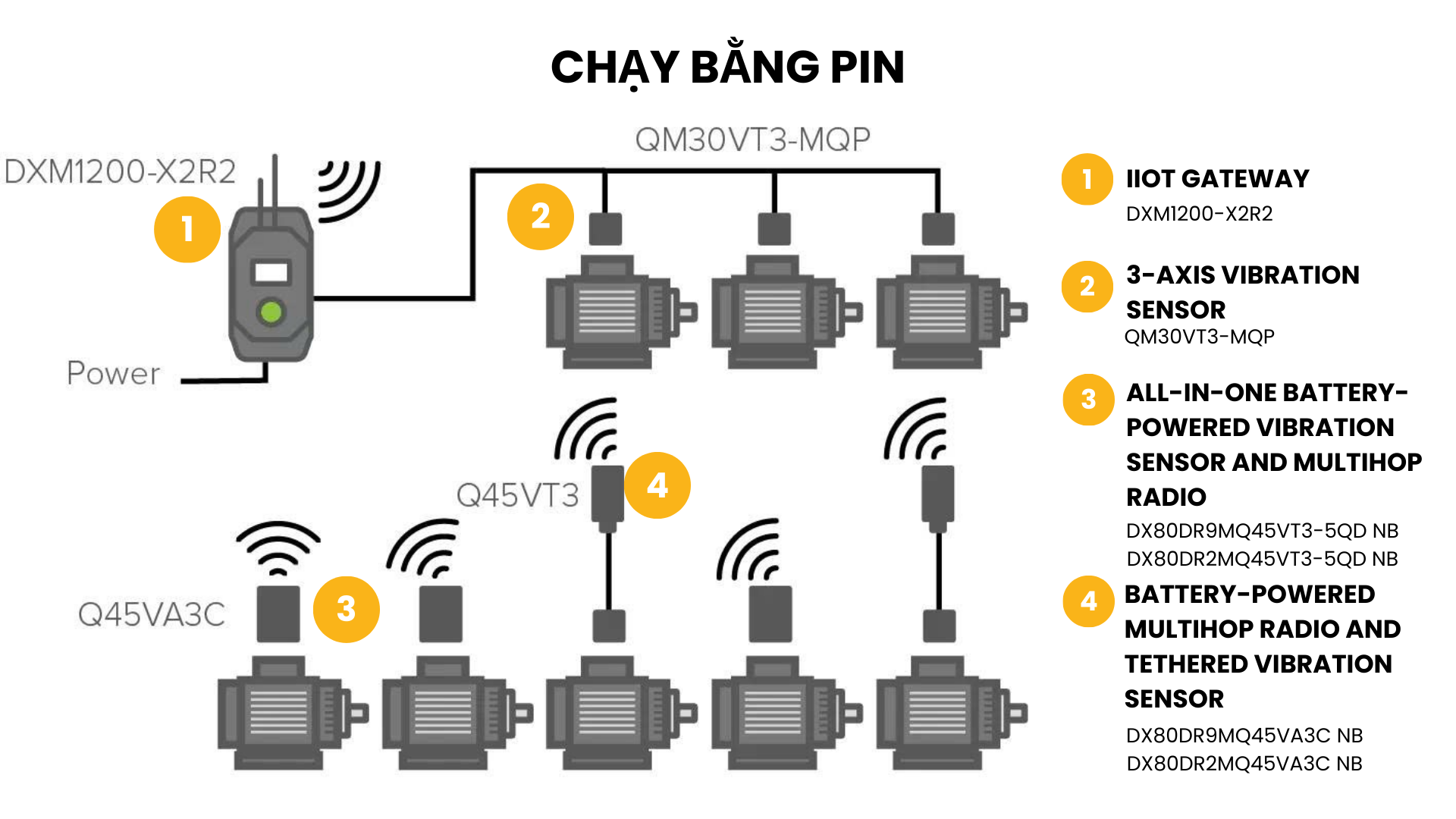

CONFIGURATION EXAMPLES

1/ Industrial Controller

DXMR90-X1E

2/ 3-Axis Vibration Sensor

QM30VT3-MQP

3/ Serial Data Radio

R70SR9MQ

Line-powered sensors are ideal when continuous data from an application is needed, or when sensors are colocated on a skid, asset, or work cell. In this example, a DXMR90-X1E controller collects data from multiple QM30VT3 vibration sensors. Three are connected directly to the controller for power and data. The others are connected to R70 radio nodes and power supplies, with the R70s sending data wirelessly to an R70 connected to the controller.

Battery-powered sensors are well-suited for facility monitoring integration performed by a third part or when a sensor is in a remote location where running power is difficult. A shown here, multiple QM30VT3 vibration sensors are battery-powered: three wireless all-in-one devices (QM45VA3C) combine the sensor with a multihop radio and battery power in a single housing, while two sensors are connected to separate multihop radios (Q45VT3). Data is sent wirelessly via radio to a DXM1200-X2R2 controller, to which line-powered vibration sensors are also directly connected.