Solve challenging applications

Sometimes due to product type, line layout or free space concerns, a standard conveyor scale model will not be suitable for certain manufacturer’s needs. When that happens, our team of experienced engineers can design the conveyor scale to meet the manufacturer’s requirements – either through the creation of a custom system or through a partnership. Work with OEM to find a common solution

Software Application Expertise

Our conveyor weighing software is constantly being improved, and as customers tell us about their unique requirements, we are always ready to add new features to make operations more efficient and easier to implement. . For example, we have implemented color-coded buttons according to customer requirements. The idea is to make it easier for operators to navigate the software to reduce user error.

Trusted by leading manufacturers

We have partnered with leading manufacturers in the food, pharmaceutical and other industries to provide customized solutions to meet their specific quality control needs.

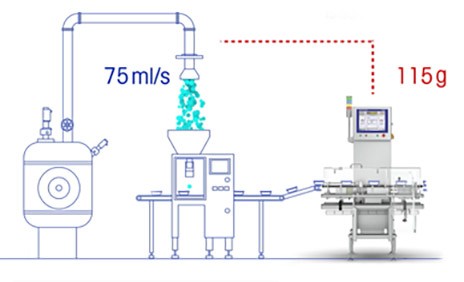

Integrated system for feedback control

Another unique system was developed in partnership with Behringer Eisele, a manufacturer of automatic steel saws for use in the forging industry. These conveyor scales measure the weight of large steel cuts to determine whether cutting to the right length is being performed.

Product handling options

Usually, one of the most important parameters for accurate weighing results is the distance and position of products as they move across the weighing surface. Products that are uniquely shaped or have a tendency to shift as they move require additional consideration when in transit to and from the conveyor scale. We have a variety of product handling mechanisms available to help stabilize and properly position products as they pass through the conveyor scale, including timing gears and screws.