Merging Artificial Intelligence with MACHINE VISION

What is Deep Learning?

From the phones in our pockets to the reality of self-driving cars, the consumer economy has begun to harness the power of deep learning neural networks. Deep learning has emerged as a foundational technology in the voice, text, and facial recognition we use in mobile devices, and is now starting to be used in many other applications — from diagnostics health to Internet security — to predict patterns and make critical business decisions. This same technology is now moving to advanced production lines for quality checks and various evaluation-based uses.

In essence, deep learning teaches robots and machines to do what comes naturally to humans: learn by example. New, low-cost hardware has made it a reality to deploy biologically inspired, multi-layered “deep” neural networks that mimic neural networks in the human brain. This gives manufacturing technology incredible new capabilities to recognize images, discern trends, and make intelligent predictions and decisions. Starting from a core logic developed during initial training, deep neural networks can continuously refine their performance as they are rendered with new images, speech, and text.

Deep learning-based image analysis combines the specificity and flexibility of human visual inspection with the reliability, consistency, and speed of a computer system. Deep learning models can accurately and iteratively address vision applications that are difficult to develop and often cannot be maintained using traditional machine vision approaches. Deep learning models can distinguish unacceptable defects while tolerating natural variations in complex patterns. And they can easily adapt to new examples without reprogramming their core algorithms.

Deep learning-based software can perform judgment-based placement, inspection, classification, and character recognition challenges more efficiently than humans or traditional machine vision solutions. system. Increasingly, leading manufacturers are turning to deep learning and artificial intelligence (AI) solutions to solve the most complex factory automation challenges.

Machine Vision in automated assembly

Gone are the days when people directly managed factory lines. Today, machines automate manufacturing, assembly, and material handling tasks. Machine vision systems equipped with precise alignment and recognition algorithms and guidance capabilities have made it possible to produce modern compact parts that cannot be manufactured by hand. On the production line, machine vision systems can reliably and repeatedly inspect hundreds or thousands of parts per minute, far beyond human inspection capabilities.

For decades, machine vision systems have taught computers to perform inspections to detect defects, contaminants, functional flaws, and other abnormalities in manufactured products. Machine vision excels in the quantitative measurement of a structured scene because of its speed, accuracy, and repeatability. Machine vision system built on suitable camera and optical resolution can easily check the details of objects too small for the human eye to see and examine them with greater confidence and fewer errors (Figure 1).

Examination by ordinary people

Machine Vision

Figure 1. People are skilled at learning by example and appreciating acceptable deviations from controls. In contrast, machine vision provides the speed and robustness that only a computer system can.

+ Speed

+ Accuracy

+ Repetition

+ Check for details that are too small to be seen by the human eye.

Deep Learning vs other testing methods

| Compared to human visual inspection, deep learning is: | Compared to traditional machine vision, deep learning is: |

| More consistent

Works 24×7 and stays the same quality on each line, each shift and each factory. |

Designed for difficult applications

Solve complex inspection, classification, and location applications that are impossible or difficult with classical rule-based algorithms. |

| More reliable

Identify any defects outside the set tolerance |

Easier configuration

Applications can be set up quickly |

| Faster

Identify defects in milliseconds, aid application speed and improve throughput |

Tolerance of variations

Handling error variations in applications that require appreciating acceptable deviations from inspection |

Changing Machine Vision

Traditional Machine Vision systems work reliably with well-manufactured, consistent parts. The product works through step-by-step filtering and rule-based algorithms that are more cost-effective than human inspection. But the algorithms become unwieldy as exceptions and errors develop. Some of the difficulties in traditional machine vision testing, such as final assembly verification, are notoriously difficult to program due to the many variables that the machine can be difficult to isolate such as lighting, color changes, and brightness. curvature and field of view (Figure 2).

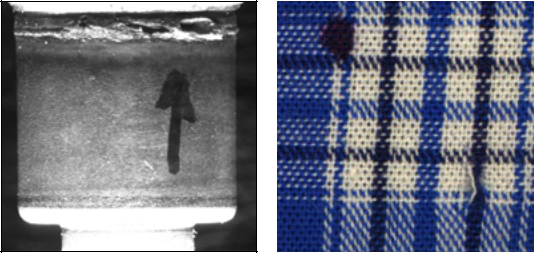

Although machine vision systems can accept some changes in the appearance of a part due to scale, rotation, and distortion, complex surface textures and image quality present challenges. serious test. The machine vision system will attempt to evaluate variation and deviation between seemingly similar parts (Figure 3). Inherent differences or anomalies may or may not be cause for rejection, depending on how the user understands and classifies them. “Functional” anomalies, which affect the function of an part, almost always result in rejection, while cosmetic anomalies may not, depending on needs and preferences. of the manufacturer. The most problematic is that these defects are difficult for traditional machine vision systems to distinguish.

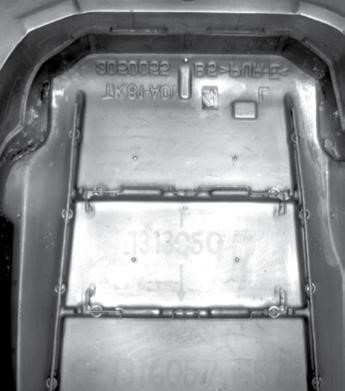

Figure 3. Confusing and dazzling backgrounds can make it difficult for traditional machine vision systems to appreciate small differences between images. In this case, a deep learning-based model will see the outside of the metal surface and the glare to check for missing wires in the car’s trim.

Figure 2. Application developers may find it difficult to program complex tests involving unpredictable bias and defects into a rule-based algorithm.

ADVANTAGES OF HUMAN TESTING

Unlike traditional machine vision, humans are adept at distinguishing between aesthetic and functional subtle flaws, and appreciate how changes in part appearance can affect perceived quality. Although limited in information processing speed, humans still have the ability to generalize. Humans are good at learning by example and have the ability to discern what really matters when it comes to minor anomalies between parts. This makes human vision the best choice, in many cases, for qualitatively explaining a complex, unstructured scene — especially those with subtle imperfections and flaws. unpredictable errors (Figure 4).

Figure 4. Examples of complex scenes where human vision is superior to discrimination.

For example, humans are much more precise when dealing with distorted and illegible characters, complex surfaces, and aesthetic defects. For many of these applications, machines cannot compete with humans because they appreciate their complexity.

DEEP LEARNING WHEN COMPLEX TESTING

Deep leaning models can help machines overcome limitations by combining the self-learning ability of testers with the speed and consistency of a computer system.

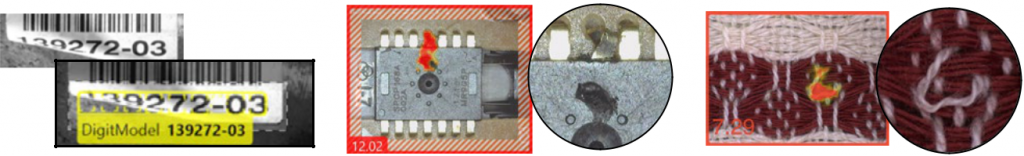

As the examples in Figure 5 show, deep learning-based image analysis is particularly well suited for the examination of cosmetic surfaces that are complex in nature: patterns vary in subtle but tolerable ways. gain and position variations may preclude the use of spatial frequency-based methods. Deep learning excels at resolving complex cosmetic and surface imperfections, such as scratches and dents on turned, brushed or polished parts. Whether used to locate, read, examine or classify features of interest, deep learning-based image analysis differs from traditional Machine Vision in its ability to conceptualize and generalize the appearance of a part based on its distinguishing features — even when those features change subtly or sometimes go astray

Figure 5. Deep learning-based image analysis excels at identifying aesthetic and functional anomalies encountered by machine vision, and it performs more quickly and reliably than human inspection People.

CHOOSE BETWEEN TRADITIONAL MACHINE VISION AND DEEP LEARNING TECHNOLOGY

The choice between traditional machine vision and deep learning depends on the type of application being solved, the amount of data being processed, and the processing power. Indeed, for its many benefits, deep learning is not the right solution for many applications. Traditional rule-based programming technologies are better at evaluating and measuring, as well as performing precise alignment. In some cases, traditional visual inspection may be the best choice to pinpoint the area of interest and deep learning to examine that area. The results of a deep learning-based inspection can then be transferred back to traditional vision to make precise measurements of the defect size and shape.

Deep learning complements rule-based approaches and it reduces the need for deep expertise in the field of vision to build an efficient testing process. Instead, deep learning has turned applications that previously required vision expertise into technical challenges that experts without vision can solve. Deep learning shifts the burden of logic from an application developer who develops and writes a rule-based algorithm to an engineer who trains the system. It also opens up a whole new range of possibilities to tackle untried applications without testers. In this way, deep learning makes machine vision easier to work with, while expanding the limits of what computers and cameras can accurately test. Figure 6 below identifies the best-suited applications for traditional machine vision and for deep learning-based approaches, including those best suited to

When to implement traditional machine vision with Deep Learning-based image analysis

Figure 6. Deep learning-based image analysis and traditional machine vision are complementary technologies, with overlapping capabilities as well as distinct areas where each excels. Some applications may involve both technologies

Conclusion

Increasingly, the industry is turning to deep learning technology to solve manufacturing inspection that is too complex, time consuming and costly to program using traditional rule-based algorithms. This will make it possible to automate applications that were not programmed before, reducing error rates and speeding up test times. Deep learning gives manufacturers the ability to solve problems that challenge traditional machine vision applications and do so with greater power and reliability.

DEEP LEARNING SOLUTIONS

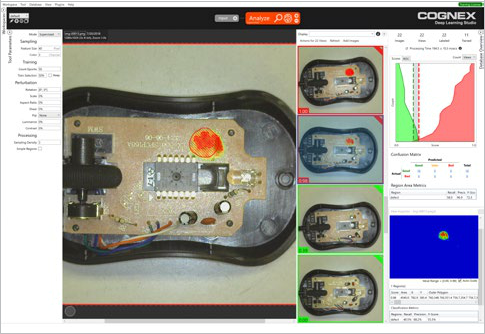

Cognex Deep Learning is the first set of deep learning-based vision solutions specifically designed for factory automation. Proven, optimized, and field-proven technology based on state-of-the-art machine learning algorithms.

Instead of following a rule-based approach to solving inspection challenges, like traditional machine vision applications, Cognex’s deep learning solutions learn to detect patterns and anomalies from objects. Reference image example. Deep learning automates and scales complex testing applications that hitherto still required testers such as defect detection and final assembly verification.

In-Sight ViDi

Deep learning applications In-Sight® ViDi implemented on smart camera In-Sight D900 without a PC, making it easy for non-programmers to access deep learning technology. The application uses the familiar and easy-to-use In-Sight software platform, which simplifies application development and factory integration.

VisionPro Deep Learning

Software VisionPro Deep Learning combined machine vision tool library (Machine Vision) Comprehensive with advanced deep learning tools within a common development and deployment framework. It simplifies the development of highly scalable vision applications and enables engineers to build flexible, highly customized deep learning solutions tailored to specific needs.