Features of Insight Laser Profiler

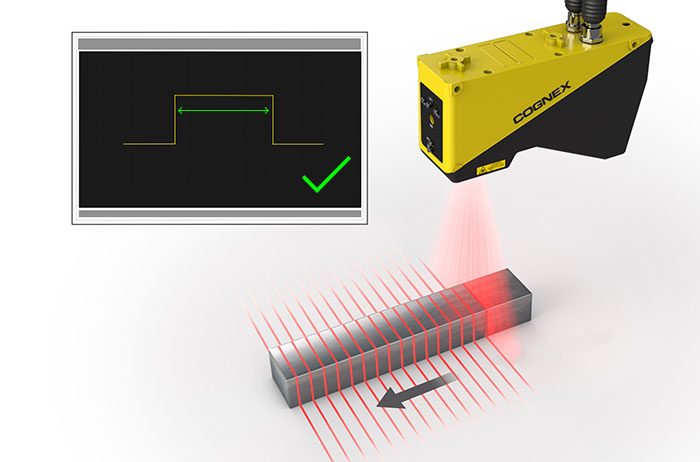

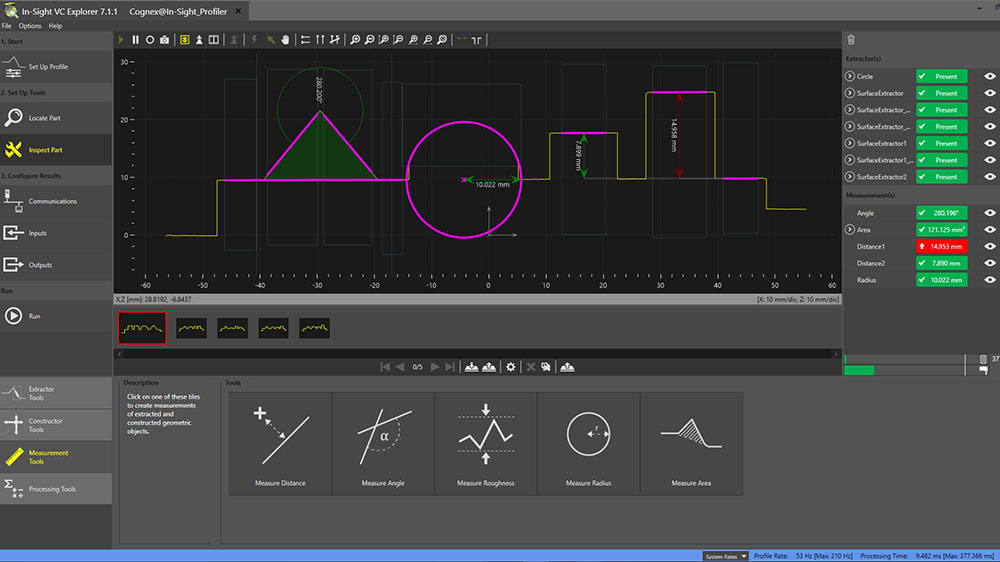

The In-Sight Laser is a measurement system used for dimensionality verification for measurement, inspection and ID applications. The In-Sight Laser is configured using the In-Sight EasyBuilder user interface. This intuitive, easy-to-use software makes it simple for manufacturing and quality engineers to develop, deploy, and support accurate and reliable measurements on the factory floor.

Set up and deploy in 4 easy steps

- Simple ID generation- The most accurate display profile optimization technology.

- Object locating – Sophisticated object detection technology reduces the need for costly fixtures and ensures measurements are taken in the correct location.

- Instrument Measurement – In-Sight Laser builds reference points, counts key features, and verifies if a product has been manufactured within tolerances.

- Result communication – applications are sent to the PLC. Measurements can be stored on the controller for downstream analysis or quality control logging.

Monitor production line activity from anywhere on the factory floor

The In-Sight Laser provides intuitive, mobile platform-independent imaging to access the HMI (human machine interface) from anywhere on the network. The HTML-based user interface allows users to monitor production line operations from any laptop, tablet, smartphone or other mobile device.

Reliable technology for reliable, repeatable results

The In-Sight laser profiler system combines Cognex displacement sensor heads with the In-Vision VC200 vision controller. Using industry-leading algorithms, the system extracts records, performs highly accurate measurements and analyzes the results. Advanced vision tools provide an accurate surface position even when the surface has imperfections.