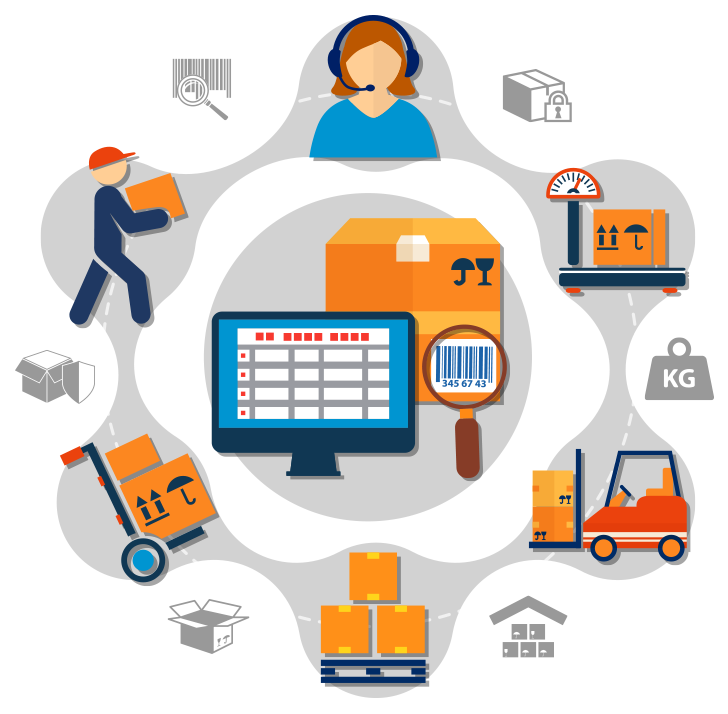

There are many modern technologies used to improve the efficiency of smart warehouse models. And here are some of the most basic technologies.

Automated Picking Tools: Automatic Picking

There are various tools that can be used to enhance the selection processes. For example, voice automated order picking, robot-robotic order picking. And pick-to-light (Pick to light is a light direction selection technology that provides an accurate and efficient method of paperless placing or sorting and assembling products.) . These technologies also utilize advanced barcode options that integrate seamlessly with your chosen management software for the fastest, most accurate automated reporting experience.

AGV: Self-propelled vehicle

With structural integrity and completeness, the design of the AGV is evolving as technology advances, but even the models that have been on the market in recent times have proven to be safer and provides a faster working process than manual labor.

Some of the most important functions of the AGV include: pallets, racks, other container storage, and even functions that control and automate the entire pick-up and return process. Robocar (AGV self-propelled vehicle) can pull pallets weighing up to 500kg at a speed of 50m/min silently and gently to the right position. AGV can work 24/7 and almost no time off

IoT – Internet of Things

The Internet of Things or IoT is a broader concept than a single technology, but it is often included in the most efficient smart warehouses in the world. As IoT is used to control so many moving components, both automated and manual, it can optimize all your processes so that their data lives in an easily accessible network. This optimizes the warehouse’s inventory control process, the workforce planning of warehouse managers and operators, and of course, an overall better customer experience through successful completion rates. work faster and more accurately.

Cobots– collaborative robots: Collaborative Robots

Cobots are one of the components that are increasingly being used in smart warehouses. Along with the AGV self-propelled vehicle, 3-axis, 4-axis, 5-axis and 6-axis robots are also increasingly used for loading and unloading applications from pallets of AGV self-propelled vehicles or automatic conveyors to arrange into positions. predetermined storage location, and vice versa.

Cobots allow warehouses to keep many of your infrastructure design and processes intact while benefiting from the optimized workflow that fully autonomous elements provide.

Automated Inventory Control Platforms: automated inventory control

In smart warehouses, when used in conjunction with a handful of other key technologies, such as “asset tags” and inventory, an automated inventory control platform is deployed to bring elements such as labor, guesswork and time factors out of traditional inventory control. To do that, most of these platforms are built to automatically count inventory and aggregate data for fast, real-time, and extremely accurate reporting that can be accessed remotely for tracking. , control and extract data of a smart warehouse.

Warehouse Management Systems: Warehouse Management System

A warehouse management system is a comprehensive software system that organizes all critical data into one platform that is easily accessible to internal users as well as any member of your supply chain. . This data organization makes for quick reporting that, when used skillfully, can be used for effective planning, even for the scenarios you’ve seen.

AS/RS: Automatic storage and retrieval system

Automated storage and retrieval systems, including automatic conveyor systems, loading conveyors, lifting systems, cranes, etc. have been around for many years, and although they have been completed successfully capabilities and accuracy, but they are still often considered expensive, cumbersome, and generally inflexible technology. Having said that, nowadays, AS/RS, is getting more and more beautiful and still gives users all its original benefits, such as: reducing/limiting labor costs, flexibly changing with ability from its modular structure, and of course increased accuracy.

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

—————

Follow VULETECH at:

► Website: https://vuletech.com/

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw