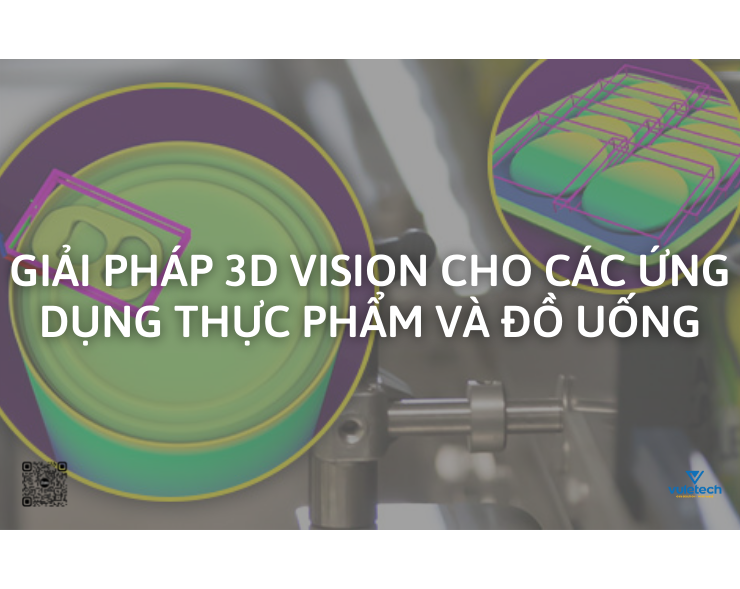

In the food and beverage industry, packaging verification helps to protect the brand’s image and eliminate spoiled products, but this system requires very high accuracy. Here are the challenges in food and beverage inspection and how they are addressed with the right machine vision solution.

Check aluminum cans:

Inspecting aluminum cans for missing or damaged parts must be done quickly to avoid bottlenecks on the production line. A small dent in a can or a bar raised just two degrees can lead to damage. These small defects are difficult or impossible to identify with the 2D imaging system. However, switching to a 3D solution can disrupt production and require retraining of workers. Every second counts in high-speed applications, where a few seconds can represent hundreds or thousands of products.

To achieve a higher level of detection without disrupting production or undertaking lengthy training programmes, Cognex developed the In-Sight 3D-L4000 vision system. This high-performance smart camera delivers patented best-quality laser images. It can detect:

- Mass or spots

- Edges

- Surface angles

- Height, etc.

With both 2D capabilities and true 3D vision, the In-Sight 3D-L4000 can run both 2D and 3D inspections of the part simultaneously. The In-Sight 3D-L4000 is available in three models to meet specific requirements for a wide range of applications, such as canning, packaging, and product inspection.

Check out the final product:

Food comes in many shapes and sizes. Identifying different candies, verifying correct coatings and decorations, and determining whether a finished product will fit inside its packaging are all complex undertakings for the system. automatic imaging system.

Brand image is important. If customers see a missing cookie, damaged cereal bar, or a battered cupcake layer on the lid, they may not buy the product and instead associate the brand with poor quality. To verify the quality of the product, 3D vision solutions are required.

The tasks include:

- Disability Detection

- Identify parts – for example, sugar-covered biscuits…

- Verify height

- Make sure the right volume

- Flatness Check

- Verification of the presence and absence of parts

High-quality optics and smart cameras are required for accurate feature detection and mass determination. The In-Sight 3D-L4000 provides the performance needed to ensure product quality. However, the biggest challenges may not be solved with the camera alone. The next application demonstrates the need for software interfaces that are easy to set up, operate, and maintain.

Check out the cereal bar:

For a cereal bar application, the key to success is finding software that works easily and efficiently without lengthy training or third-party technicians. Intuitive In-Sight software allows field technicians to quickly set up tools. Then the software takes care of the rest – identifying every pixel above and below the set plane with linear measurements and highlighting features in a simple interface to communicate the results clearly to everyone. use.

Many workers on the production line are familiar with In-Sight’s spreadsheet programming model, while new operators can learn the system in minutes. In one example, 50 new users were trained on the 3D In-Sight program in less than three hours. In addition, the high-performance smart camera In-Sight 3D-L4000 detects products that are rotated or tilted. High-quality 2K resolution, with scan rates up to 4 kHz and patented blue-spotless blue laser optics, provide a wide range of machine vision solutions with fast, accurate results and repeatable.

The In-Sight 3D-L4000’s unique blue laser optical design has several benefits including:

- 2M works safe for eyes

- More light reaches the surface than competing solutions

- Precise 3D point clouds for measurements

- The ability to scan even if one percent of the laser is blocked by debris

This last feature is an unprecedented achievement in 3D laser scanning, made possible by patented spotless laser optics. Most laser scanning applications limit the designer’s option to mount the scanner upside down because of concerns about debris blocking laser light.

A healthier technology:

When it comes to the food and beverage industry, testing can be the difference between success or millions of lost revenue. Having fewer products in a container than advertised can damage a brand’s image, and too many products can cause packaging errors. The challenges are increasing as food production lines become faster, more automated and more dynamic. Even a simple package or product line can require advanced solutions to test different volumes, surfaces and features. With an easy-to-use spreadsheet for efficient communication, the In-Sight 3D-L4000 provides accurate data to check and keep food and beverage lines active.