According to Meili Robots, mobile robots and “fleet” management software offer several advantages over manual material handling.

The term “material handling” refers to the control, movement, and protection of products and materials from production to distribution. In some cases, processes in between such as transport and storage are also included. Material handling equipment covers a wide range of automation technologies, with conveyor systems and mobile robots being among the most popular.

Since material handling is concerned with packaging, storage, transportation and delivery, it is closely associated with the manufacturing , warehousing , logistics , retail and disposal industries. To be more precise, there are 4 stages of material handling in supply chain:

- Manufacturing: First, shipments of imported components and finished products need to be moved and handled in factories and warehouses.

- Shipping: Second, the goods need to be delivered to an internal warehouse or to an external wholesaler – preferably units, for a smooth shipping process.

- Storage and storage: It is time for products to be unloaded, moved and stored in racks or racks in the warehouse.

- Distribution: Finally, products need to be picked , sorted and packaged into units, and loaded onto trucks for distribution to retailers or customers.

It’s no surprise that materials handling has become an absolutely essential part of today’s supply chain management and warehouse efficiency optimization – and the market growth numbers outweigh the profits. speak.

Growing Material Handling Market:

Even before the COVID-19 pandemic, consumer behavior was increasingly shifting towards online shopping. Material handling automation is becoming increasingly important for businesses to efficiently fulfill orders and stay competitive during supply chain disruptions.

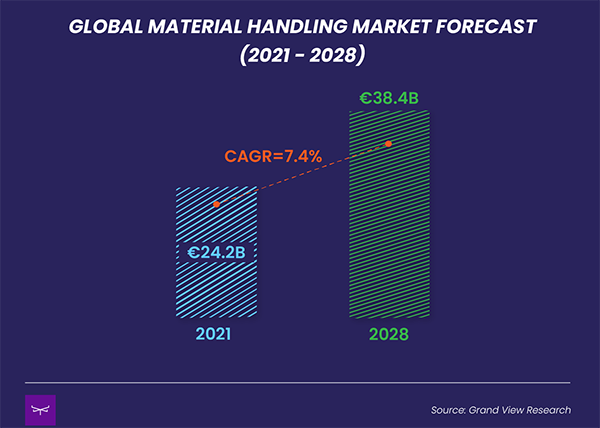

As the table on the right shows, the statistics of the global material handling market show tremendous growth potential. Currently valued at just over $27 billion (US), Grand View Research projects that the market will grow to a value of more than $43 billion by 2028, following a compound annual growth rate (CAGR) of 7.4 %.

(Image source: Meili Robots)

Manual and automatic material handling systems:

In general, we can distinguish between two types of material handling processes — manual and automatic. While human labor is flexible and established in global supply chains, workforce challenges such as retention, wages and local availability have made many operations difficult. consider building a robot.

Let’s look at the pros and cons of each of the following approaches:

Manual material handling:

- Advantages: Low initial investment when it comes to machines and technology.

- Expert: Since no technical expertise is needed, it is relatively easy for employees to adapt to new processes.

- Pro: More space, as no heavy equipment or machinery is involved.

- Child: To avoid injury, regular safety training is required.

- Con: Such processes are prone to human error.

Automatic material handling:

- Professional: Increased flexibility allows processes to be adjusted as needed.

- Con: The initial investment is high, but automated systems can save huge amounts of money in the long run.

- Advantages: Risk of injury and accident is reduced because no staff is required to lift heavy objects

- Professional: Space can be used more efficiently thanks to machines, such as being able to store products in higher places.

- Pro: Automation can help reduce inventory management errors, thus improving order fulfillment.

As is the case with most technologies, the exact system that works best for your business will depend on a number of factors such as future plans for your business and your initial budget.

While manual systems work well only for relatively small businesses operating with dynamic process handling, robotics and automation are great for businesses that handle a lot of repetitive work. repeatability and greater material volume.

Four ways to optimize material handling:

For businesses looking to optimize their material handling processes, the following steps can be a useful starting point:

- Evaluate: Regularly evaluate the health of your processes based on data relevant to your operations. Think about the number of orders processed, the number of forklifts in use and their operating costs, the overall operating costs of your facility, and more. This will help you understand where to adjust.

- Automation: Consider automation to optimize your facility’s efficiency and profitability. Robots and software can not only save a lot of time, but by being able to predict and respond to order fulfillment and material flows, they can also reduce operational costs.

- Storage and Flow: If you want to optimize your warehouse design, you need to have a deep understanding of your processes first. To do so, it is essential to analyze the movement of materials to and from different locations in your facility. This will also help determine which solution best suits your requirements.

- Smart Storage: By implementing a storage system that uses artificial intelligence to constantly learn and adapt to the environment, businesses can more easily predict and react to material flows, thereby optimizing the movement of goods throughout their facility.

Importance of task management and navigation:

As we’ve seen throughout this article, material handling automation can be a great way to optimize material flow through manufacturing, storage, and distribution facilities. If you are using — or planning to use — autonomously guided vehicles ( AGV ) or autonomous mobile robots ( AMR ), you may want to consider systems for managing navigation safety and distribution. tasks in dynamic environments.

Interoperability has emergedas a concern over the past year or so, as factories and warehouses begin to deploy robots from multiple vendors.

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

Source: Robotics