According to PMMI’s 2017 Automation Evolution report, small to mid-sized consumer packaged goods companies are starting to see the value of automating operations . Consumers are increasingly demanding more customized and personalized products. For companies that manufacture Consumer Packaged Goods (CPGs), this trend has led to an increase in SKUs. Shorter run times and more container formats add complexity to already complex packaging and manufacturing operations.

Robots and companies that produce prepackaged consumer goods

Cobots are getting a lot of attention because of the constant growth of Universal Robots and new vendors entering the market. The Odense, Denmark-based company sold its 25,000th cobot earlier this year, and it’s still seeing strong double-digit growth, said Stu Shepherd, regional sales manager for the Americas for Universal Robots. UR cobots were displayed in more than a dozen booths at the show.

In this case, what should CPG companies do?

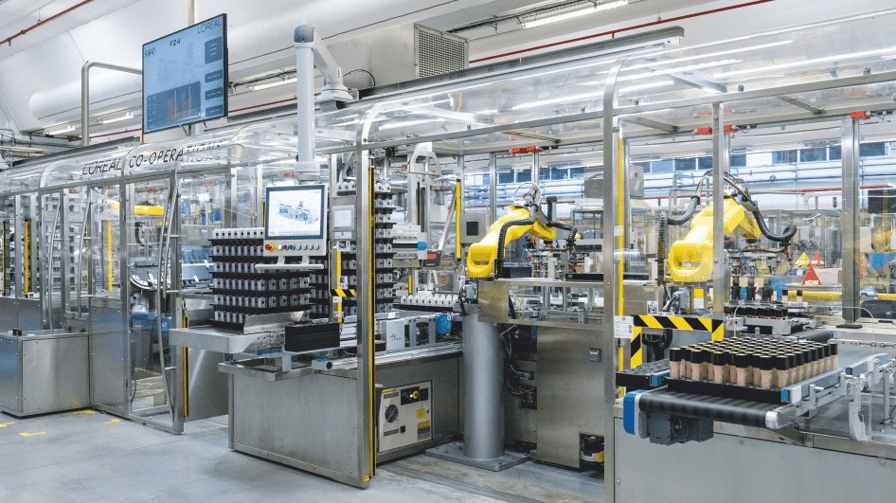

A case study from L’Oreal shows the important role robots can play in helping manufacturers meet consumer needs with complex navigation and increased efficiency.

Case Study: L’Oreal

At the L’Oreal factory in France, the company manufactures skin care products, masks and foundations. L’Oreal has developed faster operations at this plant by combining the robot with the latest in linear servo motor technology. That technology is the extended transportation system, or XTS.

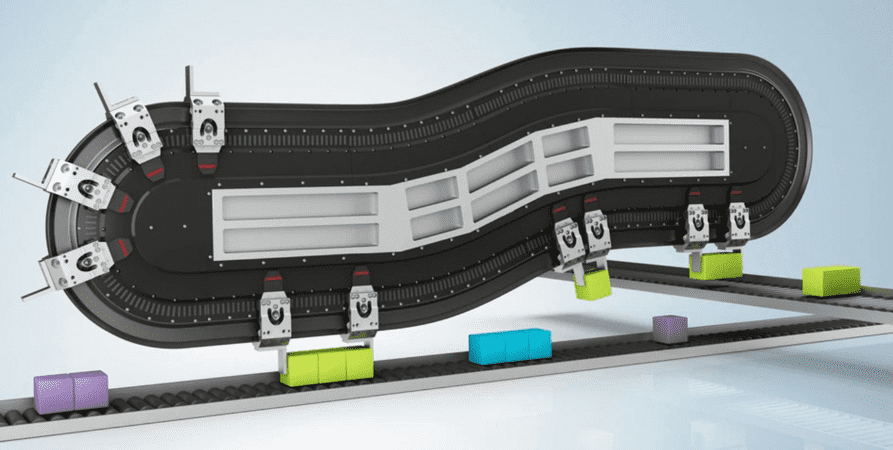

The linear mechatronic transport system implemented by L’Oreal contains all the functions required for operation including a fully integrated and modular linear motor with power electronics and position measurement , as well as non-stationary motors moving along the mechanical guide rails.

The photo below shows an XTS with 10 independent engines. L’Oreal’s application has 40 independent operating companies.

L’Oreal then added robots to handle many parts of the packaging operation. A handling robot picks up two or three empty bottles from the tray and places them in transport pins that are fastened on the XTS’s motors.

In the following stations, robots or handling systems fill bottles, install pumps or dispense droppers (depending on product), screw them in, and place a cap on top. Once all the steps are complete, the migrating devices proceed to the next operation.

Then, a laser code with the product color, batch number and expiration date is printed on the bottle and labeled. At the end of the XTS circuit, the filled bottles are robotically placed into the trays and forward.

A key advantage of the XTS is its individual control over each of its engines, with each bottle being transported through the processing stations by a single motor. Depending on the processing time required, the mover can stop for the amount of time it takes to perform an action and then move its bottle to the next step. This eliminates the need to perform different timed processing steps on separate machines. Instead, the XTS and its integrated robots reduce the five previously needed machines into a single system.

Through this integration and the compact design of the XTS, L’Oreal’s systems at this plant have been reduced by 30%. Combined with increased system throughput, productivity per unit area increases dramatically.

Thanks to the flexibility of this system, L’Oreal can better meet the growing demand for high-end cosmetics without having to expand the production floor area. On a single line, L’Oreal can now mass produce from a few hundred pieces to millions, can change colors within seconds, and can process seven types of packaging formats in as little as 40 passes. move.

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

—————

Follow VULETECH at:

► Website: https://vuletech.com/

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw