Industrial robotics applications have seen tremendous growth over the past decade, as many industries have realized the potential of industrial robots and more importantly, collaborative robots (Cobots). Cobots are low-cost industrial robots that operate safely around humans. Automated robots are more flexible than standard or traditional industrial robots, which means they can be deployed for a variety of tasks from tending and welding machines to packing and loading pallets. The majority of cobot implementations are found in manufacturing and industrial environments, but cobots can be used flexibly in a variety of fields from agriculture, healthcare to pharmaceuticals.

Read on to learn more about the capabilities of industrial robots in general, and let’s take a look at some of the most innovative and recent cobot applications.

WHAT ARE COBOTS IN INDUSTRIAL USE?

There are many industrial robot applications. While there are many ways to implement robotic technology, the goal of such machines is the same across all industries and processes – to improve manufacturing. Robots can improve the efficiency and safety of many industries by taking on dull, dirty and dangerous jobs.

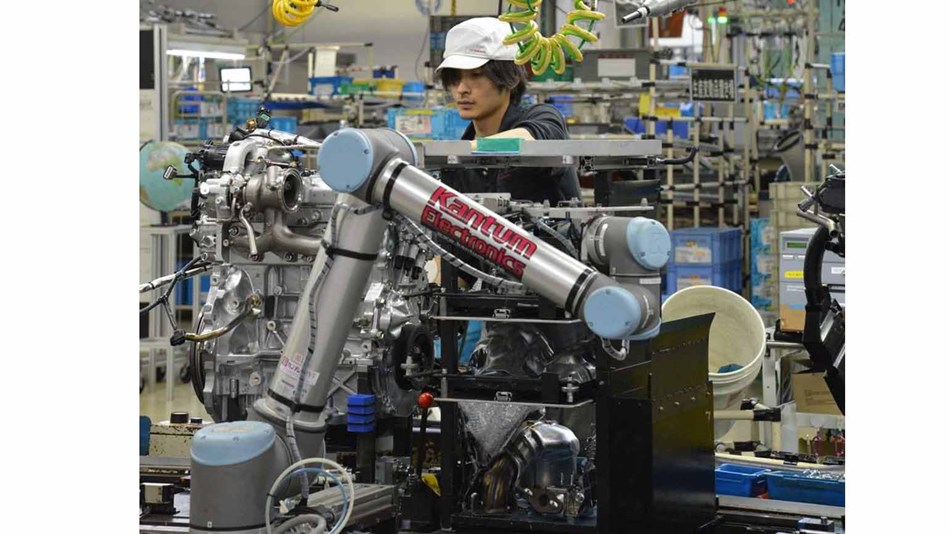

Traditional industrial applications of robots have been large machines, as well as machines that are static and difficult to reuse and reprogram. In contrast, cobots are compact and flexible, and can operate without cages or safety barriers directly next to humans.

WHAT IS THE APPLICATION OF COBOT IN INDUSTRY?

There are many collaborative robot applications in all industries. These include assembly, delivery, finishing, machine maintenance, material handling, welding, material removal, quality inspection and more. Below, we summarize three common types of robotic arm deployments.

Material handling

Material handling is one of the most dangerous jobs in manufacturing. Materials such as metals, plastics and others can pose a great risk to workers. In addition, many repetitive material handling jobs can give rise to repetitive stress injuries.

Industries that use robots in manufacturing have significantly fewer workplace injuries. Heavy materials can easily be lifted and transported across factory floors using mobile robotic platforms. Meanwhile, machine care tasks, including those involving heavy CNC machines, are also within the reach of the robotic hand from Universal Robots.

Assembly and quality assurance

Universal Robots cobots are specially designed to work together with humans and free them from tedious and difficult assembly jobs. These jobs include soldering small pieces together, drilling screws and similar assembly work.

Automated robots can also be used to assist in quality assurance during manufacturing. Unlike humans, cobots perform the same tasks, anytime, anywhere, without showing fatigue or a drop in performance. For example, the robotic arm can place a single camera in the same position to take multiple measurements and position across multiple work pieces as needed – all without the need for optical recalibration.

► Website: https://vuletech.com/

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw