In this day and age, when all products are marked with barcodes to help businesses track the life cycle of a product, if the barcode of a defective product cannot be read, then This means that the product will be rejected, in more serious cases, the business may be fined because the barcode on the product does not meet the standard quality. And the circuit code verification solution will help your business not to have this problem.

1. What is Barcode Verification?

Barcode verification is the process of classifying barcodes to let businesses know which products have satisfactory barcodes and which products have faulty barcodes. This helps businesses check and track their assets.

The 1-D and 2-D level barcode verifiers are developed based on industry standard specifications developed by international organizations such as ANSI/ISO and specialized groups such as GS1 and HIBCC, makes printing and scanning systems hassle-free, no matter where they are manufactured or processed.

Barcode verification helps confirm that a code being generated will be accepted anywhere, by any reader. This is the only and most reliable way to diagnose and fix markup errors.

2. How is barcode quality assessed?

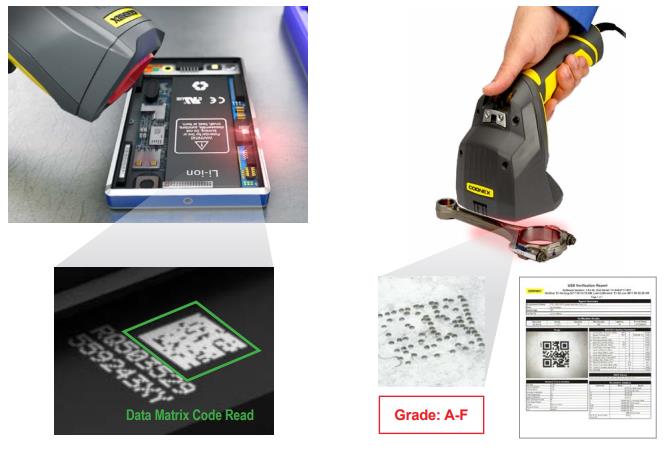

Barcode verification guides manufacturers through the marking process to produce high-quality, readable codes. Barcode verifiers analyze barcodes and assign a quality grade to them, usually represented by a letter grade (A to F) or a numerical equivalent (4 to 0). Generally, barcodes with grade C or higher are considered pass codes and are 100% scannable.

3. Barcode Verification Solution: Diagnosing and Fixing Errors

Barcode verifier and software that reports on code quality parameters and validates data for conformance to ISO/IEC 15415, ISO/IEC 15416 and AIM DPM guidelines (ISO/IEC TR 29158).

Barcode verification software provides diagnostic features to identify unsatisfactory barcode problems and provides the information needed to improve codes.

4. Benefits of barcode verification:

Barcode verification guides manufacturers through the marking process to produce high-quality codes that can be read anywhere, by anyone. From brand owners and manufacturers to packers and retailers, people across industries use barcodes to track their products from production to point of sale.

Guide manufacturers throughout the marking process and help them demonstrate compliance with quality standards.

Barcode verification is an essential quality control tool for printed codes as well as for customers receiving them, as it ensures complete scanability of barcodes along the supply chain.

Meet the quality standards and ensure the reputation of the business: verification helps to provide the necessary information for the product. An appropriate inspection system ensures barcode scanning at every level of the supply chain for increased efficiency and smoother customer-supplier relationships.

5. Difference between barcode information confirmation and barcode scanner:

While both heads are designed to read codes, the barcode verification tool ensures that the code is marked correctly and meets the quality standards of the industry. Compared to barcode readers, barcode verifiers are a superior measure of barcode readability because they standardize the range of operation between different types of readers, from cameras and lasers to handheld devices. and fixed mount.

While a barcode reader is specifically designed to read codes, a barcode verifier can:

- Make sure the data is formatted correctly

- Confirm barcodes can be read by all scanners

- Determine the reason(s) why the barcode failed to scan

- Print a report listing the barcode grades to certify they meet industry standards

- Analysis of industry standard parameters

Verifiers take longer to parse the code and generate more data than readers, which only reveals the data in the code. Verifiers analyze and report on official parameters based on international standards. These parameters measure several factors that affect the barcode reader’s ability to identify and decode codes. Verifiers test various parameters for 1-D, 2-D and direct part marking (DPM) codes based on management standards, such as ISO international standards.

6. Identify printing and marking problems

Unlike barcode readers, barcode verifiers also identify the reason(s) why the barcode won’t scan, indicating where the barcode is missing so the manufacturer can take corrective action. Printed reports that list barcode grades help certify that the code meets industry standards.

See more: LASER CODE TESTING SYSTEM ON THE ASSEMBLY

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, Ho Chi Minh City

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

Follow Vuletech more often at Facebook