Whether gasoline or other substances: the liquid tank system must always be sealed, or it becomes dangerous. After manufacturing, they are thoroughly tested before being used on vehicles. Worthmann has developed a helium leak detection system for this purpose, using high vacuum and mass spectrometry to identify even the smallest leaks in the system in just one minute. The high-vacuum angle valve of SMC’s new XLA series has the long life and required durability.

Modern machines work with a wide variety of operating materials – from lubricants and various fuels to uric acid mixtures to reduce the nitrogen oxides found in car exhaust. On top of that, leak-proof components are needed to get them where they need to be. For example, if fuel leaks in the vehicle and touches the hot engine or electrical components, it can quickly become dangerous. Worthmann offers the right solution for its leak detection system: thanks to the mass spectrometer, the system can detect even the smallest leaks of helium in a high vacuum and thus evaluate evaluate whether a part is leak-proof or not. The test system requires robust valves for safe and accurate operation.

At Worthmann Maschinenbau GmbH in Barßel-Harkebrügge near Oldenburg, highly complex machines have been developed and manufactured since 1995 – from the processing and testing lines for the fuel system to the entire production line . Thanks to state-of-the-art machinery, the 120 employees at Worthmann are also able to manufacture complex, individual assemblies. The company’s core competence is the design and construction of individual production systems and complete lines. Everything from a single source: From design to production and assembly to programming and commissioning for international customers. Maceas GmbH, specializing in test and measurement technology, is also part of the Worthmann Maschinenbau Group.

See if everything is tight

Anyone who’s ever had a flat tire on a bicycle is familiar with the principle of leak testing: the hose is filled with air and kept under water – where the air bubbles come out, there’s a hole. However, this type of testing is not enough, especially for modern vehicle systems. This is why automated leak testing systems are used, testing every component for leaks in the shortest possible time and with the highest accuracy possible.

These highly specialized systems use premium helium gas. The test portion is placed in a vacuum chamber and then vacuumed together with the chamber. The helium is then injected into the test unit as a test gas at too high a pressure. If there is a leak, the helium escapes and is pumped to a mass spectrometer, where the helium atoms can be counted. “And that’s very accurate, because the mass spectrometer itself recognizes individual helium atoms. That is why this system has a limited leak rate of 1.0 10-5 mbar l/s,” emphasizes Steffen Akkermann, project manager at Worthmann. Up to 60 workpieces per hour can be inspected with the Worthmann system.

Powerful angle valve for high vacuum

To achieve this high cycle rate, air must be rapidly drawn out of the intake manifold and test chamber to feed the test gas to the test object. For a high vacuum as pure as possible, a valve is required which, when closed, practically does not allow gas to pass through and which, nevertheless, can be operated very quickly and frequently. Christian Suchalla, Sales Engineer at SMC Germany, explains: “At high flow rates, ice crystals can also form at the deflection points of the angle valve and thereby distort test results when gas settling test in valve. The high-vacuum angle valves of the XLA series from SMC have an effective solution for this: thanks to the heating element, they can be heated up to 150 degrees Celsius and thus effectively prevent freezing at the deflection point.

Angle valves are used in leak testing systems in several important ways: They guide air and test gas into and out of the test chamber and workpiece and serve as a connection to the mass spectrometer. Christian Suchalla: “The valves are fitted with bellows and remain closed if they are not pressurized.” This means that they practically do not exceed the speed, which greatly increases the escape rate of the test chamber and the workpiece. Alternatively, a pump with a lower capacity can be used – this increases the efficiency of the entire system. Add to that the durability of the new XLA angle valves: they are guaranteed to withstand up to 2 million cycles. In addition, the bellows and pneumatic actuators of each individual valve can be replaced separately. That saves on maintenance costs, because the entire valve doesn’t have to be replaced. At the same time, the modular structure greatly reduces maintenance costs.

Pure vacuum thanks to strong angle valve

With the XLA high-vacuum angle valve from SMC, the leak detection system from Worthmann provides a quick and powerful solution for manifold production. “Further efficiency gains are envisioned in the future by controlling angle valves through our modular SY3000 valve terminals,” says Christian Suchalla. Other applications for the robust XLA valve, such as vacuum drying systems in the food industry or aluminum coating systems for automotive headlights – i.e. wherever a high degree of vacuum is required purer the better.

[Figure 1] Detect when there is a leak: Leak detection systems from Worthmann Maschinenbau GmbH identify leaks quickly and reliably thanks to the XLA high-vacuum angle valves from SMC.

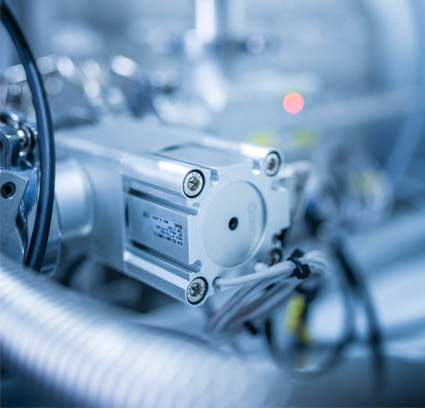

[Figure 2 + 3] Thinking outside: The new angle valves of the XLA series from SMC have exchangeable bellows seals and pneumatic actuators – this saves time and money on maintenance as the whole valve does not have to be replaced.

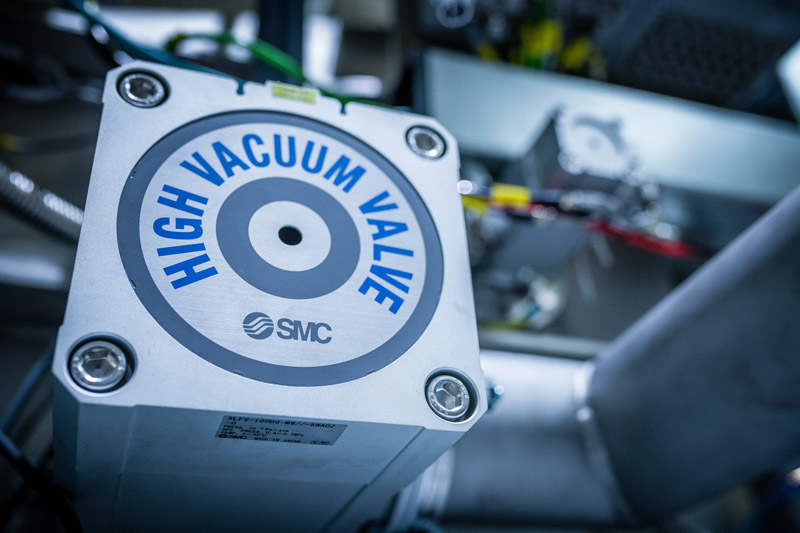

[Figure 4] If it’s cold: Thanks to an externally mounted heater, the new high-vacuum angle valves of the XLA series from SMC can prevent freezing during operation and thus ensure exceptional test results. exact distinction.