Top manufacturer

With over 1.6 million systems installed at facilities around the world and over thirty-six years of experience, Cognex focuses solely on industrial machine vision and barcode reading technology. reader) based on the image. Implemented by the world’s leading machine builders and original equipment manufacturers (OEMs), Cognex’s patented vision tools and hardware are suitable for integration into semiconductor and board machinery. printed circuit boards (PCBs), and offers custom multi-camera alignment solutions for the production of displays, assembly modules, and complete consumer devices. Today, electronic hardware OEMs use Cognex products to take their device performance to the next level.

Cognex addresses customs electronics and electronics applications with leading vision and reporting technology.

With the largest investment in R&D and a global technical support team, Cognex is the preferred machine vision provider for electronics OEMs and machine builders. Today, OEM machine builders rely on Cognex for vision and ID solutions to meet their customers’ demanding requirements and deliver precise, reliable, and high-performance machines.

DEEP LEARNING TECHNOLOGIES

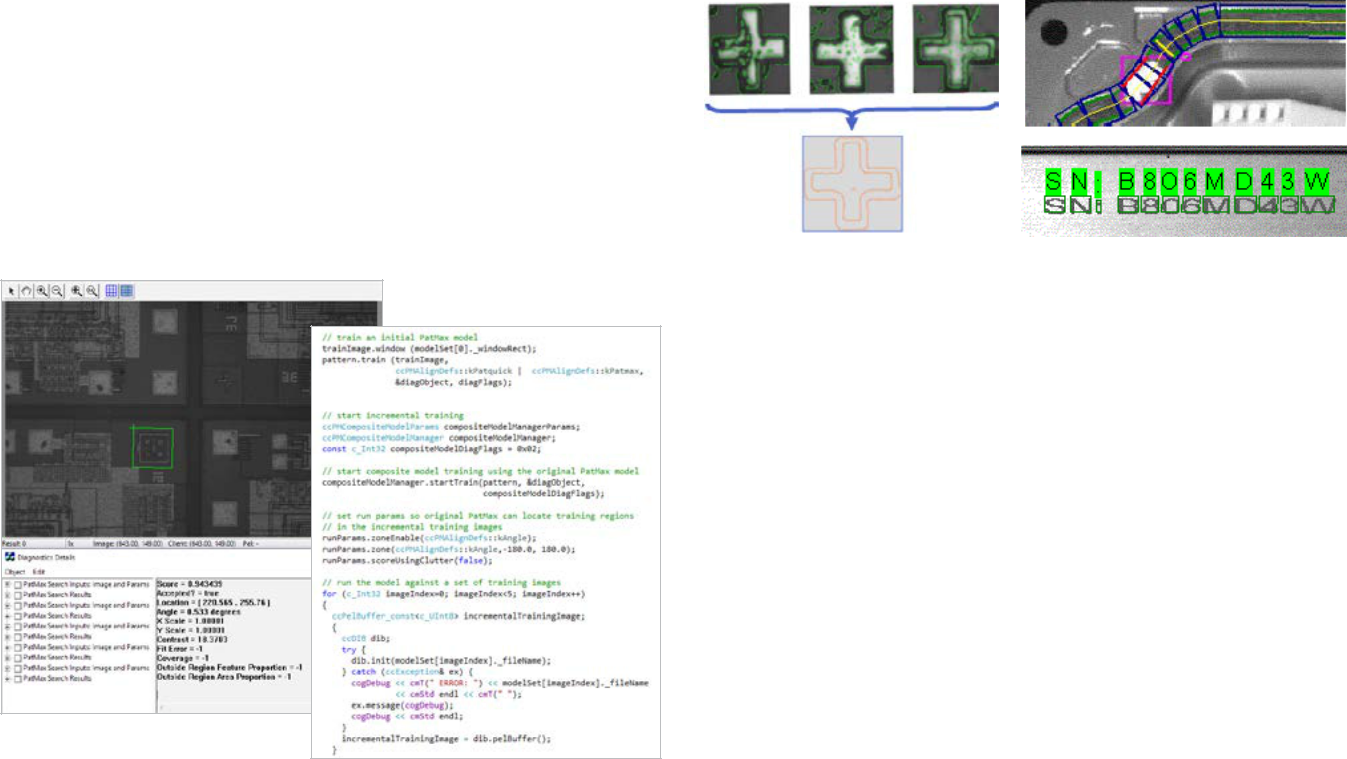

Pattern matching technology

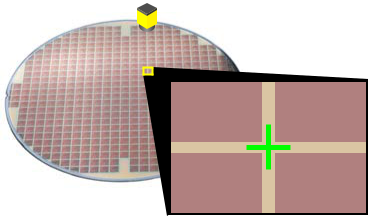

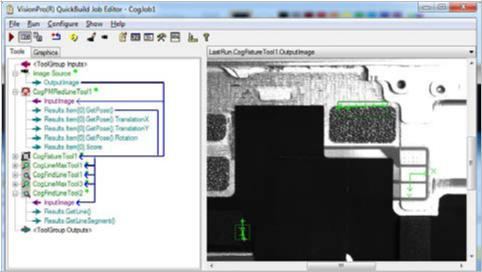

Pattern-finding technology accurately and reliably locates wafers, benchmarks, bends, node cuts and other features with up to 1/40 pixel accuracy in tough conditions. The Auto Adjust PatMax feature automatically removes the influence of noise and lighting effects. Multi-Model PatMax locates instances of multiple samples in a single runtime image.

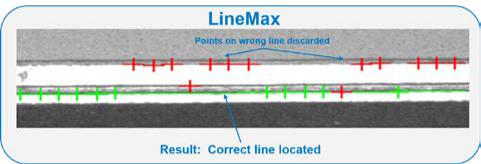

LineMax . Line Locator

The pathfinder accurately extracts and locates edge features that create lines on low-contrast or noisy images. Used in applications without molds or benchmarks, LineMax handles chamfers and other difficult edges with ease.

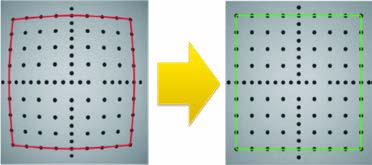

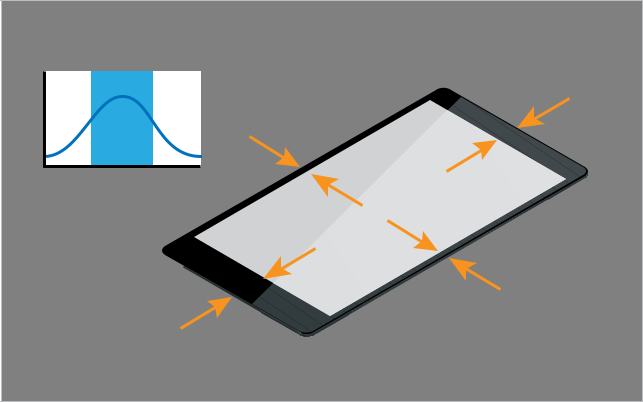

Calibration technology

Auto-Calibration (calibration) technology corrects lens, perspective and area errors with high precision, motion area and physical coordinate space. Automatic setup ensures consistent machine-to-machine performance. Ultra-Calibration technology corrects non-linear distortions associated with multi-camera applications, enabling one-time alignment, limiting errors and reducing cycle times.

Cognex ViDi . deep learning-based image analysis

Cognex ViDi is software based on deep learning for industrial image analysis and is optimized for complex surface inspection and difficult to read optical character recognition. Cognex ViDi uses neural network analysis to inspect and classify images, outperforming the best quality testers.

ELECTRONIC HARDWARE SOLUTIONS

AlignPlus Screen Alignment

Cognex AlignPlus is a vision solution designed for high precision alignment applications in OLED display manufacturing, touch panel and FPD lamination, gluing, screen printing of coated glass and module assembly. Machine vision tools include patented manual and eye calibration, a pathfinder in difficult conditions like chamfered edges, and pattern-matching vision tools . Designed as a configurable template, AlignPlus integrates quickly with a wide range of camera designs and runs on PC

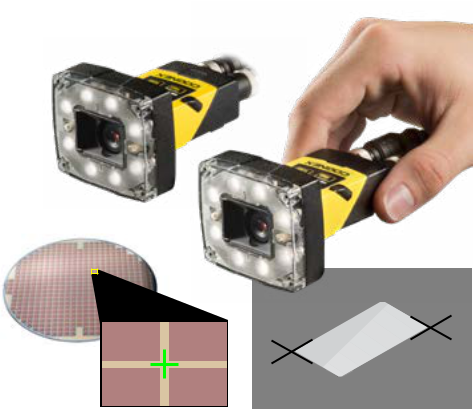

Alignment sensor AS200

The AS200 alignment sensor is specifically designed to provide line-of-sight alignment for the motion stage or robot control. The fully self-contained sensor with integrated modular lens and light makes installation simple and quick. Sensor configuration is done with a simple operator interface without programming. Motion vision correction automatically launches at the touch of a button. High performance with compact design and simple deployment, the AS200 sensor is the preferred choice for line of sight alignment for machines and equipment used in electronic assembly.

Semiconductor components and SMT . solutions

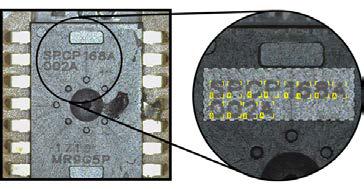

ViDi Blue-Read

Cognex’s deep learning-based OCR & OCV software uses a multi-font library to instantly recognize characters during AOI testing. The Blue-Read engine can easily retrain on application-specific fonts and misread characters. Dramatically reduces development time and provides the most accurate character recognition and verification

ViDi Blue-Read

Cognex’s deep learning-based OCR & OCV software uses a multi-font library to instantly recognize characters during AOI testing. The Blue-Read engine can easily retrain on application-specific fonts and misread characters. Dramatically reduces development time and provides the most accurate character recognition and verification

PC VISION SOFTWARE AND COMPUTER HARDWARE

Software VisionPro

Leading PC-based vision software designed for setting up and implementing 2D and 3D vision applications with a wide range of industrial cameras and framers. The extensive .net class library and user controls fully integrate the VisionPro software into OEMs and host machines. A library of pattern matching (PatMax), blob, caliper, line position (LineMax), image filtering, OCR (OCRMax) and OCV tools perform a wide range of functions, from position to object. geometry and inspection to identification, measurement, and alignment, as well as specialized functions dedicated to semiconductor and electronic applications.

Cognex vision library (CVL)

Cognex vision tools help OEMs build the widest range of machine vision applications with maximum flexibility. CVL allows developers to write their own vision applications , configure multithreading, and access all tool properties and options with completely platform independence.

Cognex industrial cameras and framers

Regardless of the software development environment, Cognex Industrial Cameras (CIC) and framers provide fast, reliable image acquisition designed for easy integration with Cognex VisionPro and CVL software and access to a comprehensive tool library. The GigE Vision and Camera Link cameras support standard image sources, including digital, color, monochrome, area scan, line scan, high resolution, multichannel, and multichannel acquisition.

MANUFACTURING SUPERIOR COMPONENTS AND ASSEMBLY IN CIRCUIT BOARD ONLY

Businesses cannot manufacture semiconductors and cannot assemble printed circuit boards (PCBs) without machine vision. Cognex provides OEMs and machine builders with advanced alignment, inspection and identification technology that is critical in front-end wafer processing, back-end component assembly, and PCB filling. Throughout the manufacturing process, Cognex tools improve automation, accuracy, product quality and productivity.

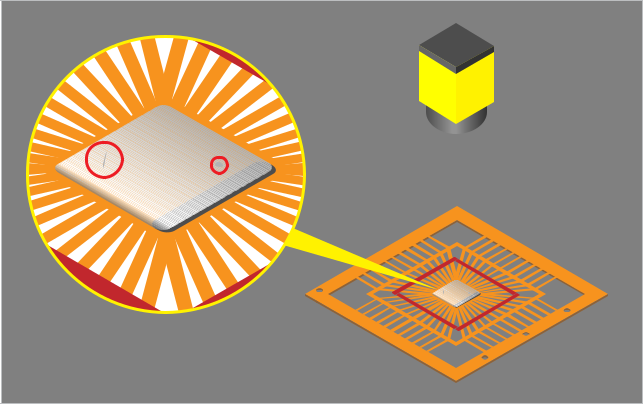

Straightening the semiconductor wafer (wafer)

PatMax technology provides fast, accurate and precise wafer and template placement for test, probe, mount, slicing and wafer inspection devices.

Identification of IC packages and semiconductor wafers (wafers)

The In-Sight 1740 series readers decode difficult-to-read wafer ID markings. The DataMan reader tracks lead frames and microchip packages through final assembly and device testing.

Semiconductor test

Machine vision inspects wafers and treats defects.

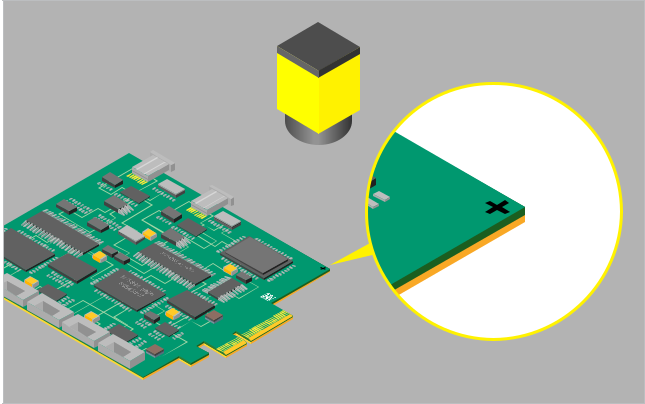

Ensure PCB alignment

PatMax technology accurately and reliably locates fiducial marks, used for alignment in screen printing, fitting and inspection.

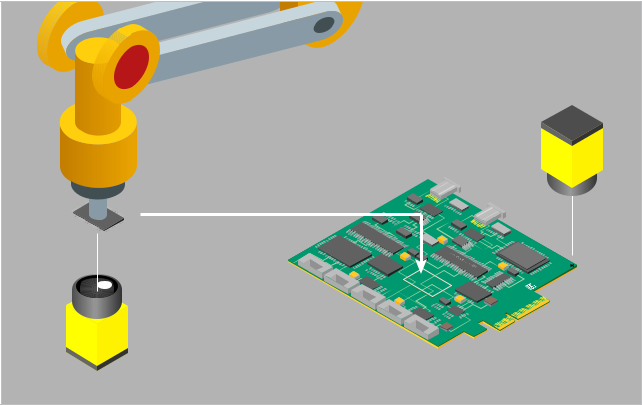

PCB Positioning Guide

Machine vision guides the selection and placement of components on the PCB.

Check PCBA

2D and 3D machine vision systems examine the PCBAs for the proper position, orientation, and identity of the components.

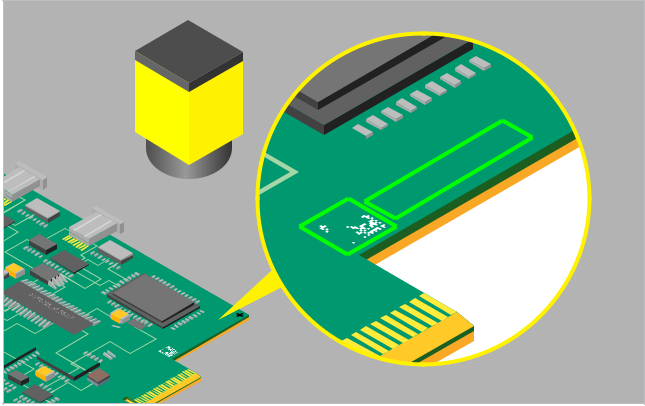

Identify electronic circuit boards

Barcode reader technology reads 1-D and 2-D codes on PCBA for traceability.

MANUFACTURING OLED AND LCD SCREEN AND MODULE Assembling

OLED and LCD display manufacturers face unprecedented challenges: How to meet the demand for micrometer-level accuracy? How to reduce downtime and support machines? Cognex’s high-precision machine alignment, measurement and care capabilities solve these problems and more. Cognex offers a full range of solutions for OLED/LCD panel and display module assembly, as well as other electronic hardware and modules. With powerful machine vision, barcode readers, robot vision (VGR) and multi-camera alignment solutions, Cognex provides OEMs and machine builders with the power and the flexibility to meet their stringent quality and production standards.

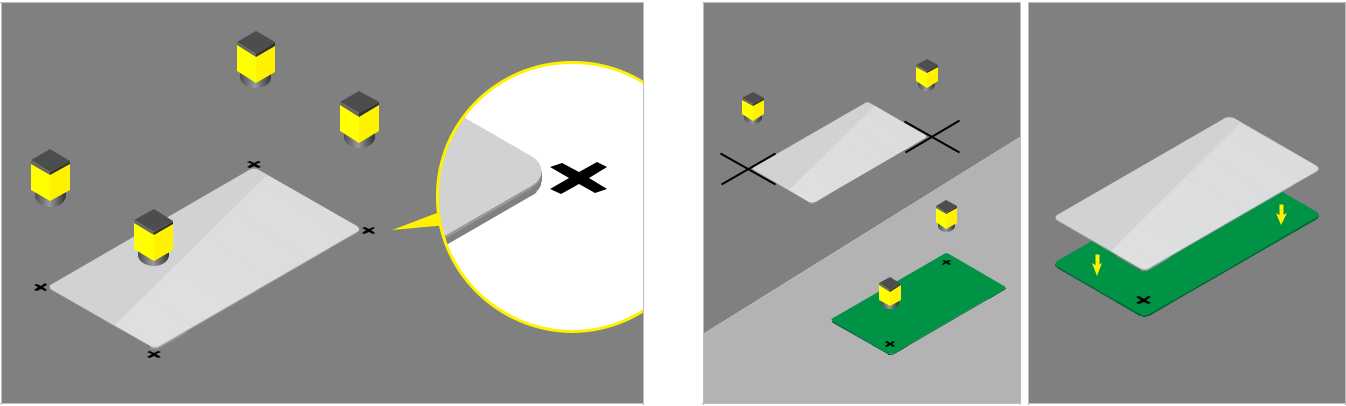

Golden Posture Alignment

Cognex vision assist alignment brings parts to a pre-established ideal position, necessary for applications such as screen printing on glass.

Measure

Vision Cognex offers 100% online monitoring of the assembly process using metrology tools to calculate CPK measurements.

Relative posture alignment

Cognex aligns the two parts relative to each other during panel manufacturing, lamination, bonding and glass assembly.

Machine control with VGR

The vision-oriented robot will independently control the machine during the manufacturing and rolling process of the panel

COGNEX GLOBAL SUPPORT

Cognex serves international customers from offices throughout the Americas, Europe and Asia and through a global network of highly trained partners, system integrators and distributors. From development to implementation, Cognex is here to help you get your vision system up and running as quickly as possible.

VISION CONSTRUCTION

2D VISION SYSTEM

Cognex machine vision systems have the ability to inspect, identify and guide parts. The product is easy to deploy and provides reliable, repeatable performance for the toughest applications.

- Industry-grade with a library of advanced visual tools

- High-speed image acquisition and processing

- Flexibility in application and integration beyond

3D EASY LASER FILTER

The Cognex In-Sight laser profiling machine and 3D vision system provide the easiest, most powerful and flexible to achieve reliable and accurate measurement results for the most challenging 3D applications.

- Factory-calibrated sensors deliver fast scan speeds

- Industry-leading vision software with powerful 2D and 3D toolset

- Compact, IP65-rated design withstands harsh factory environments

SMALL Image-Based Barcode Reader

Cognex industrial barcode readers and mobile terminals with patented algorithms provide the highest reading speeds for 1-D, 2-D and DPM codes regardless of barcode symbology, size , quality, printing method or surface.

- Cut the cost

- Increase throughput

- Traceability Control

In Vietnam, Vuletech is one of the companies that receive Cognex’s machine vision and barcode reader solutions. For more detailed information, please contact:

Vu Le Technology Co., Ltd

Address: 27 Xuan Quynh, Gia Hoa KDC, Phuoc Long B Ward, District 9, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com