A wide range of standard and bespoke solutions for food and beverage applications

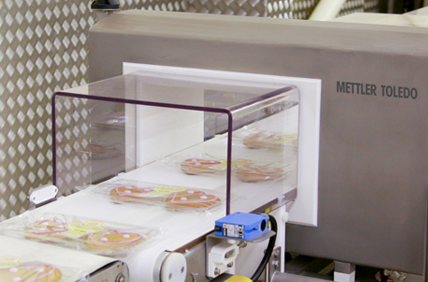

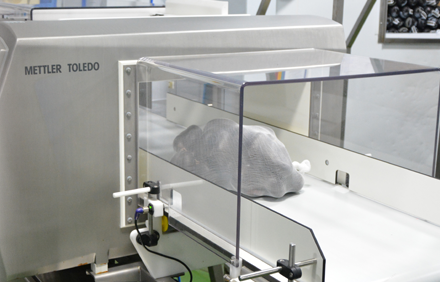

Conveyor System Integrated Food Metal Detectors are specifically designed to seamlessly integrate with industrial tunnel metal detectors, enabling contamination detection in food and non-food processing applications . All Mettler Toledo Safeline tunnel metal detectors can be integrated with standard conveyor systems or designed specifically to completely automate the product inspection process.

Flexible solutions to support manufacturer requirements

Our versatile conveyorized food metal detector systems can be designed and engineered to suit specific process requirements, light to heavy-duty food and non-food applications, works in almost any work environment. From simple stop-when-detect systems to fully automated detect-and-discard systems, a wide range of product rejection devices are available for food and non-food processing applications.

Advanced due diligence features

Each metal detector with a conveyor system comes with advanced due diligence options to improve inspection solution control and management, ensuring critical control point (CCP) performance. High metal current and safe operation.

Metal detection systems are not obsolete

Selected designs of conveyor systems in food metal detectors allow food and non-food manufacturers to configure the right features for the process, ensuring metal detection systems. not outdated. Every conveyor system incorporates sustainable construction standards, providing consistent and consistent performance across the line regardless of the working environment.

More than just a metal detector

While installing a food metal detector system can help reduce the risk, in some cases the likelihood of metal contamination reaching consumers is still too high. The main cause research point is procedural and system failure rather than metal detector failure; However, due diligence improves the control and management level of the inspection system – this ensures that critical control points (CCPs) deliver high-performance metal detection. and increase the level of unsafe functionality.

A solution that can change now and in the future

Selection of metal detection system types (with the ability to configure feature sets to suit your process) ensures that metal detectors are fully future-accessible and scalable along with your business needs. All systems incorporate robust construction standards to deliver consistent, reliable online performance regardless of the work environment.