Currently, many factories have used machine vision aka machine vision to replace humans, making it possible for the production system to automatically take pictures of products and check for 100% product defects with high detail and accuracy, while ensuring productivity. system, helping the factory save costs and bring many benefits to businesses.

I. Machine vision – What is machine vision?

One of the simplest ways to understand machine vision is to think of it as the “eyes” of a machine. Machine vision relies on protected digital sensors inside industrial cameras with specialized optics for image acquisition, so that computer hardware and software can process, analyze, and measure different characteristics to make decisions. Businesses use machine vision systems in a variety of ways to improve the quality and efficiency of their manufacturing operations, while reducing production costs.

II. Application of machine vision in industry:

To achieve accurate, reliable and repeatable results, vision system part locators must be intelligent enough to quickly and accurately compare products on the production line :

1. Guide the Robot:

Guide the Machine Robot can determine the position and orientation of a product, compare it to specified tolerances and ensure it is at the correct angle to verify proper assembly.

Next, the Robot Guide can be used to report position and orientation, allowing the Robot to determine the position of the part or machine to pick up, release, assemble the component…

Machine vision guidance achieves much greater speed and accuracy than manual positioning in tasks such as sorting parts on or off pallets, packing parts off conveyor belts, finding parts and align parts for assembly with other parts, place parts on work shelves, or remove parts from crates.

Cognex’s machine vision devices have the advantages of compact design along with the ability to process data and transmit signals at high speed; can be quickly integrated with any type of Robot.

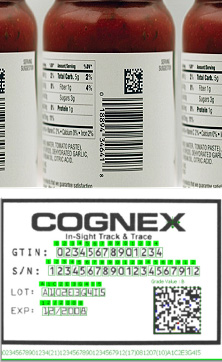

2. Recognition: machine vision allows technology to read codes and alphanumeric characters

The machine vision system can recognize the part that reads barcodes (1-D), data matrix codes (2-D), direct part markings (DPM) and characters printed on parts and labels. and packages.

An optical character recognition (OCR) system that reads alphanumeric characters without prior knowledge, while an optical character verification (OCV) system confirms the presence of a character string.

In addition, the system can identify parts by locating a unique pattern or identify items based on color, shape or size. DPM applications mark codes or strings of characters directly into the part.

Manufacturers in all industries commonly use this technique to combat defects, monitor process control and quality control metrics, and quantify problem areas in the plant.

3. Measurement and calibration: Measure distance and position to check specifications

Machine vision systems can measure and calculate the distance between two or more points or geometrical locations on a product and determine if these metrics meet specifications. Otherwise, the system sends an error signal to the machine controller, triggering a mechanism that refuses to push the object off the conveyor belt.

In effect, a fixed-mount camera will record images of products as it passes through the camera’s field of view, and the vision system will use software to calculate the distances between different points in the field. Picture. Because many machine vision systems can measure object features within 0.0254 millimeters, and solve some applications traditionally handled by contact measurement.

4. Inspection: Identify defects, irregularities and other manufacturing defects

The machine vision system will inspect and detect defects, impurities and other abnormalities in products on the production line.

Examples include testing tablets for flaws, monitors to verify icons, or touchscreens to measure backlight contrast. Machine vision can also help ensure product and packaging matching in the food and pharmaceutical industries, and check safety seals, caps and rings on bottles.

III. The benefits of machine vision: Improve quality and productivity, while reducing production costs.

The machine vision system operates smoothly with high reliability and stability. In addition, the system is capable of capturing a lot of information with high accuracy in evaluating product appearance, finding defects as well as collecting data to direct the activities of Robots or other equipment. other device.

Furthermore, machine vision systems provide safety benefits by reducing human involvement in the production process, protecting workers from hazardous environments, and preventing human intervention in the production area. secret area.

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa KDC, Phuoc Long B Ward, District 9, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com