The use of adhesive tape in factories and factories increases the amount of plastic waste released into the environment, affecting the natural environment and people. However, with Nordson’s glue spray solution, which is currently being applied in most industries today, businesses do not need to worry about the problem of harming the environment. In addition, the glue spray solution from Nordson brings precision injection technology for hot melt glue or cold glue applied in many industries to help manufacturers: reduce costs, increase productivity and improve product quality as well as product appearance.

I. In which industry is the glue spray solution applied?

1. Industries:

Currently, the industries in general and products in particular applying glue sprayers are listed as: Food and beverage industry, pharmaceutical industry, packaging industry, wood industry, mattress industry, electronics industry, and industry. Automotive, Diaper industry, …

2. Nordson Company – the leader in glue spray solution technology:

Nordson is a world leader in providing solutions for the packaging and electronics industries. Nordson Glue Spray Systems are standard systems widely used in the global packaging industry. Manufacturing industries use this application as packaging for the food industry, labels for bottling applications, cans.

Nordson ‘s technology is used in the production of many everyday consumer products. As a leading supplier to the nonwovens industry, such as baby diapers, diaper pants, feminine hygiene products, surgical gowns, wipes and towels, Nordson equipment is Used in spray applications, applying adhesives, cosmetic primers or fragrance oils to these products.

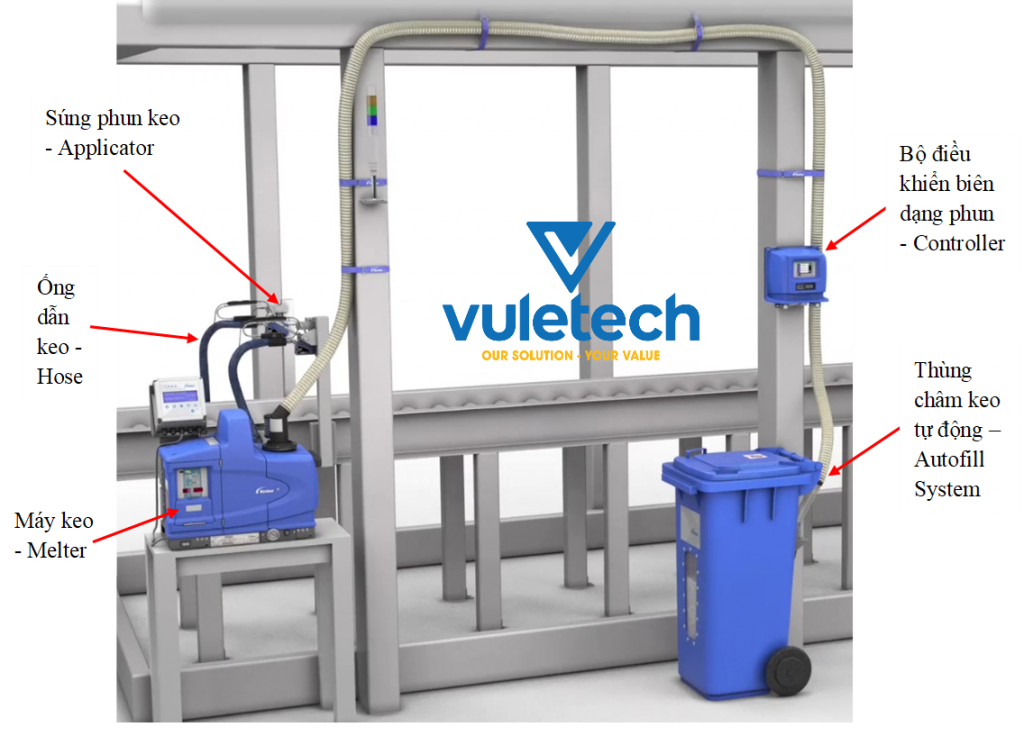

II. Structure of Nordson glue spraying system:

1. Glue machine – Melter:

The glue furnace is responsible for melting the glue to a set temperature before it is pumped out the glue pipe to the spray gun.

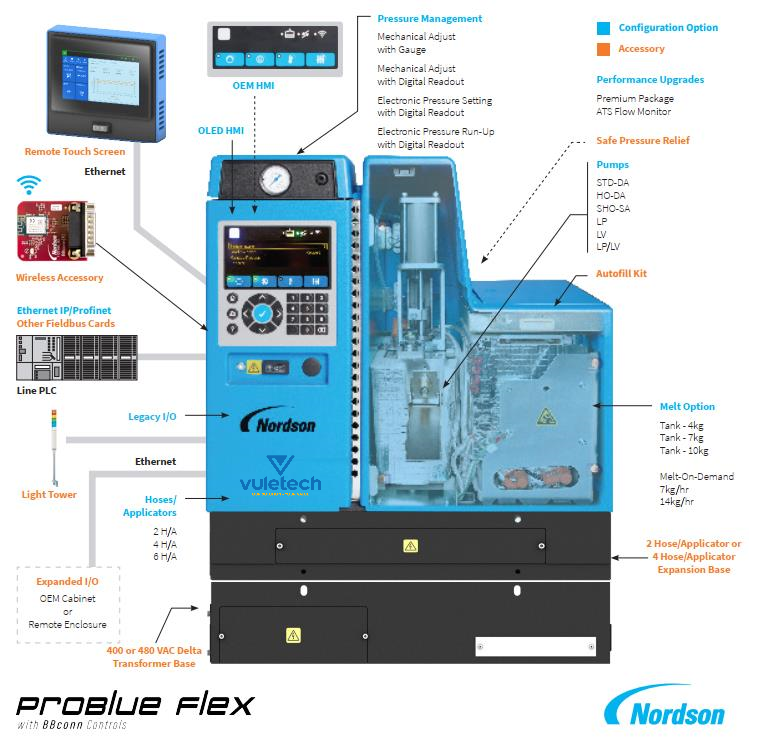

ProBlue® Flex Melter is the next generation of smart glue injection technology from the world’s leading manufacturer. The modular design solution, which can be easily upgraded in the future, gives users more flexibility, improved accuracy, better connectivity and easier system integration, etc.

Basic parts of glue melting machine – melter:

- Glue furnace – Glue Tank: Heating melts the glue in the tank by thermistor to the set temperature

- Pumping system: depending on the actual application, a piston pump or a suitable roaster will be used

- Pneumatic system: supplying and regulating compressed air for glue pump

- Circuit board and control screen system: signal processing and transmission

- I/O or Ethernet connectivity: enhanced connectivity

- Display screen OLED or OEM HMI

2. Glue conduit:

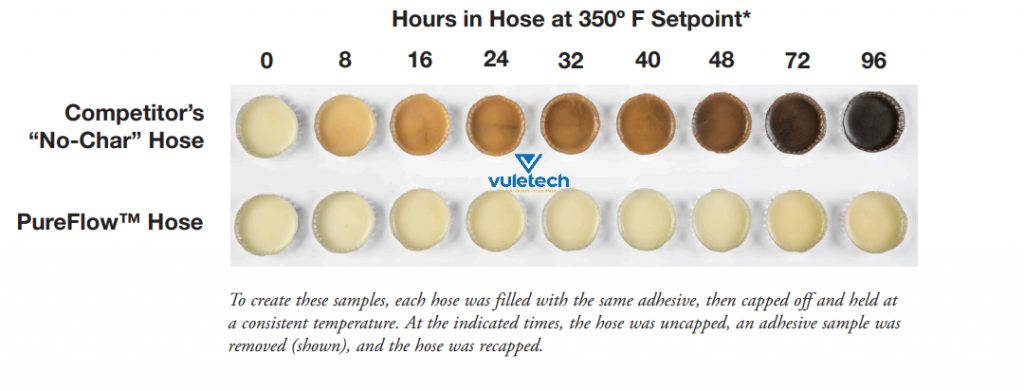

The glue pipe has the function of leading hot glue from the glue pot to the gun and heating to reach the set temperature, keeping the glue from degrading. The structure of the pipe includes the core of the conduit and the outer layer of insulation, in the middle is a resistance wiring to heat the line and use a temperature sensor to send a signal to the glue sprayer.

The technology and material of the duct determine the quality of the glue during use. High-tech glue pipes will limit the glue burning during the glue heating process in the tube. The less the glue burns, the less likely it will be to clog the glue and stop the machine.

3. Pattern controller – Pattern controller

Controller – Pattern controller makes programming of spray adhesive profiles simple, accurate and reliable.

Nordson’s Spectra system is the next generation of controllers that reduce the complexity of programming injection profiles while improving product quality and increasing productivity.

In addition, there is also the feature of remembering the established profiles to save time for users.

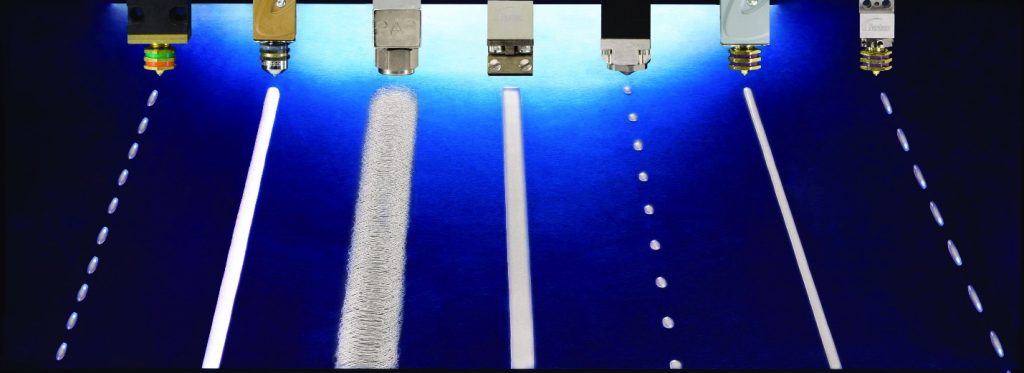

4. Glue gun – Applicator/Gun:

- This is the most important part in the glue injection system. Depending on the needs of each application, the company will tailor it to suit the intended use.

- There are many types of glue spray such as line spray (Bead), point spray (Dot), spiral spray (Swirl), sweep (Slot), …

- The nozzle can be changed, for each purpose of use.

Glue line parameters can be customized such as glue length, glue line distance, finished product output, glue injection speed, etc.

5. Automatic gluing system

The Fulfill® Retrofit Adhesive Fill Kit is attached to the glue pot and automatically refills when the level sensor sends a signal. Automatic glue injection helps save labor, limit contact with chemicals and especially improve the efficiency of the glue spray system when limiting glue burning and protecting the pump.

III. Types of hot melt adhesives used in Nordson spray solutions:

Depending on the application and adhesive material, businesses will use different types of hot melt glue. Hot melt glue includes 4 main types: EVA, PO, PSA, PUR.

Hot melt glue is usually in a solid state, does not contain volatile organic compounds, is not affected by air humidity, this is convenient for the process of storing, preserving or transporting products, helping Save cost and labor a lot.

Hotmelt glue will have two main parameters:

- Adhesion: adhesive adhesion to the surface of the object.

- Cohesion: adhesion, bonding of the glue itself.

|

|

IV. Advantages of using Nordson glue spray solution:

1. Cost reduction compared to using tape:

The glue spray solution from Nordson helps the factory to use a small amount of hot melt glue on each product, which is much more cost-effective than using duct tape. The payback period for the glue injection system is only 1-2 years.

2. Stronger than using duct tape, avoid product loss:

Switching to hot melt spray solution improves stickiness and is more durable than duct tape. The use of glue spray also helps businesses easily check the integrity of the product packaging, easily identify if product loss occurs.

3. Make the product look more professional and aesthetic

Using glue spray helps the product look more aesthetic, the product also creates sympathy for consumers, increasing the likelihood of purchasing.

4. Environmental friendliness:

Using spray glue in production helps products not to slip when overlapping, moves easily, does not need to use shrink film, making it environmentally friendly and cost-effective.

Introduction video about Problue Nordson:

Vuletech specializes in providing Nordson glue spray solutions. For more detailed information, please contact:

Vu Le Technology Co., Ltd

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, Ho Chi Minh City

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com