Fire and explosion accidents often cause extremely serious damage to both people and property. Fire and explosion safety is essential for any business to protect the company’s assets as well as the safety of its employees.

Knowing that, the manufacturer Pizzato Elettrica gave Pizzato electrical safety equipment ATEX explosion-proof standards. To learn more about this standard, please follow the article below.

1. What is ATEX explosion-proof standard?

ATEX is a European law that regulates equipment and allowable working environments in potentially explosive atmospheres. The name ATEX comes from the French word ATmosphères (Atmosphere) and EXplosibles (Explosive).

ATEX consists of 2 rules:

- Directive 2014/34/EU (also known as ATEX95): regulates equipment and protective systems for use in potentially explosive atmospheres

- Directive 99/92/EC (also known as ATEX137): stipulates the minimum requirements to improve safety and protect the health of people working in environments with high risk of explosion.

2. Classification of flammable and explosive environments:

The ATEX137 standard classifies two types of potentially explosive atmospheres, depending on the presence of flammable gas or dust in the area. These two environments are classified into three zones, each according to the frequency and duration of the environment. Areas in explosive gas atmospheres are classified into zones 0, 1 and 2, and explosive dusty environments in zones 20, 21 and 22:

- Zone 0/20: A place where flammable gas or dust is constantly present. Perpetual danger. Requires class 1 equipment.

Zone 1/21: where occasional flammability or dust is a potential hazard. Requires class 2 equipment.

Zone 2/22: A place where there is no possibility of flammable gas or dust in normal operation or, if present, only for a short time or due to a fault. Requires Class 3 . equipment

It is the end user’s responsibility to identify and classify the different areas and install the appropriate equipment.

The ATEX explosion-proof standard is also meant to prevent ignition from the surface of equipment when gas or explosive gas is present. The housing of a Pizzato electrical safety device is made of methane and stainless steel, specially designed to isolate sparks or fire incidents inside the device.

3. List of equipment according to ATEX and IEC standards:

According to the ATEX directive 2014/34/EU, equipment is classified into two main groups:

- Group I: mining equipment and systems

- Group II: equipment and systems for all other applications

Equipment of group I is divided into the next two categories according to the degree of protection required:

- Category M1: Equipment designed to ensure a very high level of protection

- Class M2: Equipment designed to guarantee a high degree of protection

Equipment of group II is divided into three classes according to the degree of protection required:

- Class 1: Equipment designed to guarantee a very high degree of protection (for use in zones 0 and 20, 1 and 21, 2 and 22)

- Class 2: Equipment designed to ensure a high degree of protection (uses for zones 1 and 21, 2 and 22)

- Class 3: Equipment designed to provide a normal degree of protection (for use in zones 2 and 22)

Table 1 – Classification of environment and equipment according to ATEX and IEC 60079-0 . standards

| Environment type | Device Features | |||||||

| Application areas | Flammable substances | The environment is potentially explosive | Classification of potentially explosive environments | According to ATEX standard 2014/34/EU | According to IEC 60079-0 | |||

| The group | EPL | |||||||

| Mining | M1M2 | I | I | MaMb | Very high

Tall |

|||

| Surface | Gas | Continuous explosive environment & for a long time

There is a possibility of fire and explosion

The environment is not potentially explosive, but if it does, it will happen in a short time. |

0

1

2 |

1G

2G

3G |

II |

II |

Ga

Gb

Gc |

Very high

Tall

Normal |

| Dust | Continuous explosive environment & for a long time

There is a possibility of fire and explosion

The environment is not potentially explosive, but if it does, it will happen in a short time. |

20

21

22 |

1D

2D

3D |

III |

Da

Db

Dc

|

Very high

Tall

Normal |

||

4. Protection measures:

In order to avoid the risk of explosion caused by the electromechanical unit in an explosive atmosphere, various protective measures can be implemented:

– Use enclosures to enclose the hazardous part to limit explosions to the interior of the enclosure itself;

– Avoid contact between hot spots and potentially explosive atmospheres by intermixing solids, liquids or gases;

– Take measures to limit the generation of dangerous hot spots, eliminate the possibility of a breakdown, or limit the power of the system so that it is not sufficient to cause an ignition.

Different modes of protection have been developed and standardized for each of these modes as listed in the following table:

Table 2 – Protective measures and applicable standards

| Protective Measures | Icon | Engraving on the product | Gas Zone | Dust Zone | IEC / EN . Standard |

| General requirements | / | / | 0,1,2 | 20,21,22 | IEC 60079-0EN 60079-0 |

| Oil soak | Ex obEx oc | 12 | / | IEC 60079-6EN 60079-6 | |

| Supercharger cover | Ex pvEx pxb

Ex pyb Ex pzc |

1,21

1 2 |

/21

21 22 |

IEC 60079-2EN 60079-2 | |

| Dusty | Ex q | 1 | / | IEC 60079-5EN 60079-5 | |

| Flame resistant cover | Ex daEx db

Ex dc |

01

2 |

/ | IEC 60079-1EN 60079-1 | |

| Increased safety | Ex ebEx ec | 12 | / | IEC 60079-7EN 60079-7 | |

| Safe inside | Ex iaEx ib

Ex ic |

01

2 |

2021

22 |

IEC 60079-11EN 60079-11

|

|

| Sealed | Ex maEx mb

Ex mc |

01

2 |

2021

22 |

IEC 60079-18EN 60079-18 | |

| No sparks | Ex nAEx nC

Ex nR |

22

2 |

/ | IEC 60079-15EN 60079-15 | |

| Protective case | Ex taEx tb

Ex tc |

/

|

2021

22 |

IEC 60079-31EN 60079-31 | |

| Optical radiation | Ex op isEx op pr

Ex op sh |

0,1,21,2

0,1,2 |

20,21,2221,22

20,21,22 |

IEC 60079-28EN 60079-28 |

Table 3 – Protection class

| Class | T1 | T2 | T3 | T4 | T5 | T6 |

| Maximum temperature for device surfaceị | 450 degrees C | 300 degrees C | 200 degrees C | 135 degrees C | 100 degrees C | 85 degrees C |

Table 4 – Gas classification (extracted from IEC / CENELEC / NEC 505)

| I | IIA | IIB | IIC | |

| T1 | Methane | Propan, công nghiệp mêtan, etan,benzen, amoniac, axit axetic, cacbon monoxit, metanol, toluen | Acrylonitrile | Hydrogen |

| T2 | Ethanol, amyl, acetate, butane | Ethylene | Acetylene | |

| T3 | Nafta, benzine, esano | Hydrogen sulfide | ||

| T4 | Acetaldehyde | Ethyl ether | ||

| T5 | ||||

| T6 | Carbon disulfide |

Table 5- Dust class

| IIIA | IIIB | IIIC |

| Flammable dust | Non-conductive dust | Conductive dust |

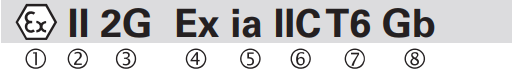

For example:

I. Equipment in Gas environment

Equipment in places where gas is present:

- EU symbol

- Device group (see table 1)

- Protection categories (see table 1)

- Prefix for safety devices according to IEC/EN standards

- Protection type (see table 2)

- Gas classification (see table 4)

- Temperature class (see table 3)

- According to EPL according to IEC 60079-0 (see table 1)

II. Equipment in dusty environment:

Equipment in dusty environment:

- EU symbol

- Device group (see table 1)

- Protection categories (see table 1)

- Prefix for safety devices according to IEC/EN standards

- Protection type (see table 2)

- Dust classification (see table 5)

- Maximum surface temperature of the device

- EPL account. according to IEC 60079-0 (see table 1)

Material: Standards ATEX of electrical safety equipment Pizzato

In Vietnam, Vuletech is the exclusive distributor of Pizzato Elettrica’s cruise switch products. For more detailed information, please contact:

Vu Le Technology Co., Ltd

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com