Consumer product applications have different requirements than industrial applications. Information and images on packaging play an important role in brand recognition, communication and even consumer safety.

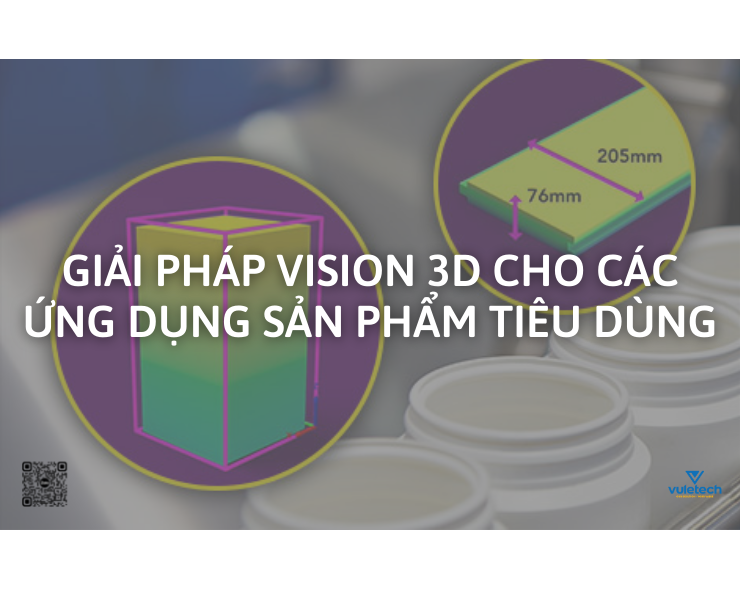

The following three vignettes show how quickly and easily the In-Sight 3D-L4000 vision system provides both 2D and 3D capabilities for consumer product applications.

Check pain reliever labels and packaging:

A painkiller manufacturer that needs a machine vision system to check labels and packaging can:

- Check box

- Defect detection

- Confirm the presence and readability of the label

The In-Sight 3D-L4000 was chosen for its capabilities and easy-to-use software. With an advanced smart camera and 2D and 3D software working simultaneously in a single compact design, setup is quick and intuitive. The system verified packaging and label quality and the results were communicated to a simple user interface. Furthermore, the user-friendly interface allows in-house technicians and operators to manage, monitor, and change software as needed to meet specific application requirements. The In-Sight 3D-L4000 was quickly integrated into the painkiller production line, successfully preserving package quality, brand recognition and consumer safety.

As part of the packaged goods inspection process, the In-Sight 3D-L4000 smart camera detects 3D features by the displacement image of a projected laser line. High-quality 2K resolution and patented blue laser speckle-free optics allow the camera to capture details on labels, text, and images on the surface of packages. These 2D capabilities leverage tools in the industry-proven Cognex In-Sight software. The software has also been upgraded, with a new set of 3D tools to tackle multiple machine vision challenges at once.

Additionally, the unique blue laser optical design of the In-Sight 3D-L4000 has several benefits including:

- Safe operation for eyes

- More light reaches the surface than competing solutions

- Precise 3D point clouds for measurements

- The ability to scan even if one percent of the laser is blocked by debris

This last feature is an unprecedented achievement in 3D laser scanning, made possible by patented spotless laser optics. Most laser scanning applications limit the designer’s option to mount the scanner upside down because of concerns about debris blocking laser light.

Check the most suitable volume:

Some system vision applications take longer to integrate than others. Typically, the more complex the processes, the more time and cost is required to integrate. However, with new lean technology, the situation is changing. Here’s an example of how a consumer product manufacturer quickly tackled the challenge of complex 2D and 3D visual inspection. In a shoe inspection system, a vision system is required to:

- Check the presence of both shoes

- Measure the volume to determine the size of the shoe

For this inspection, the In-Sight 3D-L4000 smart camera with In-Sight software and 2D and 3D tools provided quick setup and easy integration for accurate, scalable results. reproducible.. The In-Sight 3D-L4000’s accurate mass data determined that both shoes were in the box and the shoe size verified. This 3D solution used cutting-edge 3D technology to expand what can be achieved in the consumer product environment with short turnaround times.

High precision surface inspection:

In another scenario, the In-Sight 3D-L4000 tested the flooring. The smart camera detected 3D defects in the flooring surface, such as bumps and dents, while the 2D capability verified that the surface was free of visual defects such as paint stains. The continuous inspection capabilities of the smart camera are important due to the length of the panel and the speed of the process.

The In-Sight 3D-L4000’s unique spotless laser system is hardened against debris that blocks laser light through a unique optical solution. As a result, designers can confidently install the In-Sight 3D-L4000 upside down, scanning the bottom of the board without fear that airborne contaminants will render the system useless.

Machine vision solutions for every application and skill level:

Cognex’s In-Sight 3D-L4000 vision system comes with In-Sight software that allows users to quickly integrate and change tools. All data is clearly presented in a user-friendly Spreadsheet environment. Technicians and operators can monitor, manage and maintain complex jobs with minimal training.

The In-Sight 3D-L4000 consumer product inspection applications succeed in detecting defects and 2D and 3D surface quality. With a compact design, the smart camera is easy to integrate and manage. Finally, the intuitive and extensible software provides flexibility for future inspection requirements and applications.

Watch video: