Vision Sensor is no longer strange to businesses today, especially in factory automation. With the ability to solve repetitive inspection tasks quickly and objectively, vision sensor systems are increasingly being used in production lines.

I. What is vision sensor system?

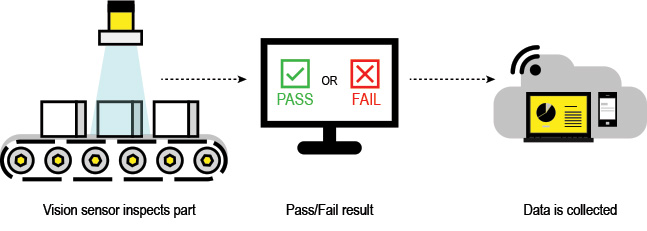

Vision sensor is a type of machine vision system designed for simple product fault finding. As presence/absence test, providing pass/fail results on automatic production lines at high speed:

- The bottle cap is of the wrong type or is deviated

- Electronic circuit board is missing components

- Packaging stamps are blurred, wrong, lack of focus

Vision sensor relies on pre-set templates in terms of features, colors, and product recognition. And most of the sensors usually support connecting to the server to notify the system whether a product is present or passed the test.

II. HOW DOES VISION SENSOR WORK?

First, the Vision sensor will collect images by taking a picture of the product, then the “photo” will be saved in memory, and processed and analyzed with parameters such as alignment. , contrast (contrast), index of brightness (Brightness), area (Area), Angle (Edge), length (Length), diameter (diameter) and count (Object Counting) etc…. Finally, Vision Sensor bases on the collected and analyzed data to give output results.

More specifically, vision sensors can be linked to factory and enterprise networks, allowing any workstation in the factory to view results, images and data for process control. Depending on the specific system or application, the vision software configures camera parameters, makes pass/fail decisions, communicates with the factory floor, and supports HMI development. Most vision sensors:

- No programming required

- Provides easy setup instructions through a user-friendly visual software interface

- Easy integration into larger systems

- Offers single-point and multi-point inspection with dedicated processing

- Provides built-in Ethernet communication

- Data can be exchanged with other systems to communicate results and trigger further testing phases

III. APPS OF VISION SENSOR

Vision sensors ensure products are defect-free and meet stringent quality standards.

Companies in many industries including heavy manufacturing, food and beverage, automotive, electronics, logistics and transportation rely on vision sensors to perform simple pass/fail checks that help ensure The product and packaging are fault-free and meet strict quality standards. By using vision sensors at key process points, defects can be detected earlier in the manufacturing process and equipment problems can be identified faster.

By minimizing defects, vision sensors can help manufacturers increase productivity, and increase profits. With a wide range of vision sensor systems and the ability to perform multiple tests per target, vision sensors can cut cycle times and improve product quality.

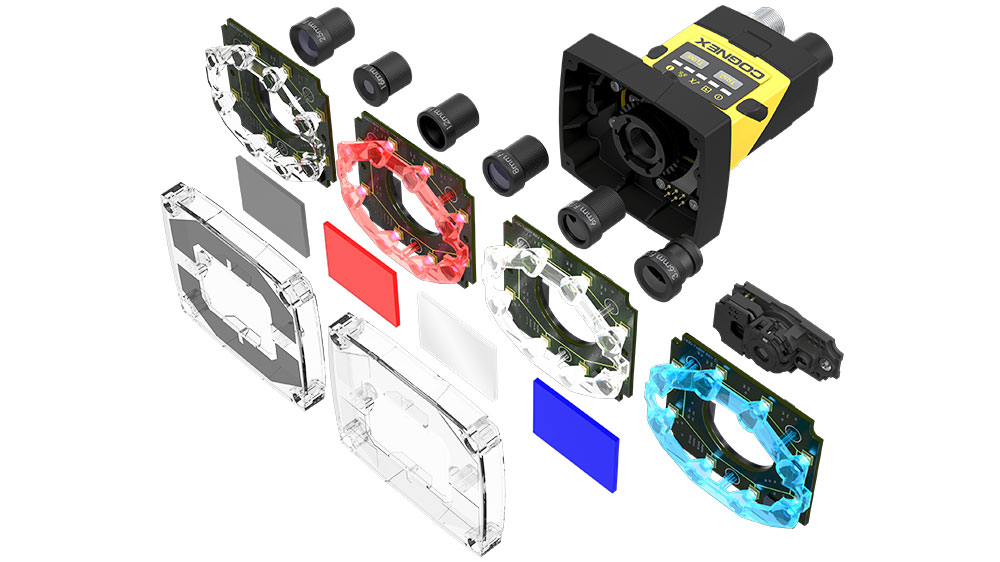

IV. Structure of vision sensor system:

In general, there are many machine vision systems on the market today, but these vision systems all have the following common components:

- Lighting equipment: help get the best image

- Image acquisition device – lens: helps to get the image of the product.

- Image sensor: help classify, mark, identify products.

- Vision processor: helps detect product defects and recognize barcodes

- Communication system: connect to bring images to the server.

See also: LASER CODE TESTING SYSTEM ON BELT AT ASSEMBLY LINE

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com