I. Project: Solder wire on PCB

In the line, workers have to perform spot welding manually, so the following situation occurs:

The time to complete a welding spot is too long

Does not meet productivity requirements

The welding points are quite bad, do not meet aesthetic needs.

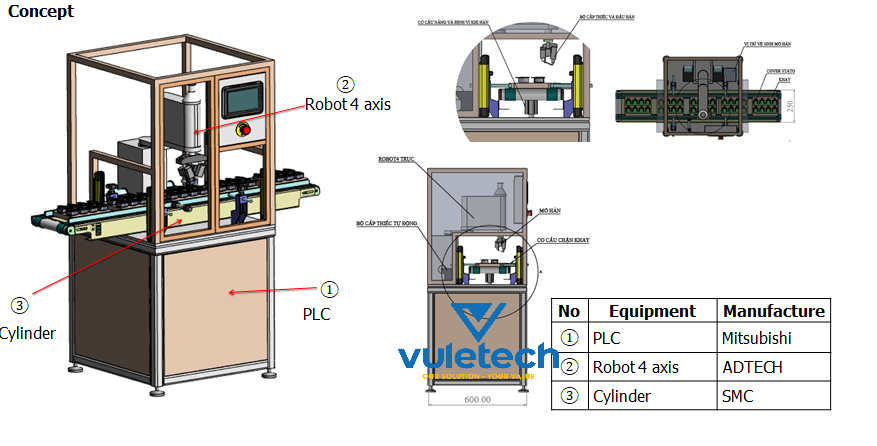

The customer gave the problem and VULETECH based on the provided data, designed and manufactured an automatic double-head welding system, reducing labor in spot welding, optimizing productivity and saving time.

II. Structure of the electronic circuit board two-headed welding machine:

The two-headed welding robot of electronic circuit boards is integrated by VULETECH from Scada Adtech AR4125 Robot, Hunter 372 welding equipment, circuit board conveyor. In addition, the product is equipped with a Pizzato safety device.

1. Scara Adtech AR4215 Robot:

Adtech AR4215 Scara 4-Axis Robot is made up of Robot body and controller (hardware and software). The robot is made up of a Panasonic Servo motor and a Japanese Harmoni Drive gearbox. Scara Adtech AR4215 robot for high performance is often applied in the automotive industry, semiconductor industry and electronics industry.

2. Hunter 372 welding equipment:

Hunter 372 welding equipment includes welding source, control system, welding gun wire feeder to help:

Reduce the problem of splashing out during welding

Helps improve weld quality

Quick heat recovery

Feeding speed, volume, duration and duration can be adjusted

Automatic and manual feeding mode.

2.1. Detailed description:

| 1 | Power Consumption | 90W |

| 2 | Temperature range | 220°C to 480°C |

| 3 | Độ ổn định nhiệt độ | ± 2°C |

| 4 | Tip to Ground Resistance | < 2 Ω |

| 5 | Tip Leaking Voltage | < 2mV |

| 6 | Feeding speed/s | Khoảng 2,7mm – 27mm |

| 7 | Feeding time | 0 ~ 2.7 sec. |

| 8 | Feeding length | 0 ~ 150mm |

| 9 | Backup time | 0 ~ 0.9s cho 0 – 25mm |

| 10 | Suitable meridians | 0.5mm ~ 1.6mm |

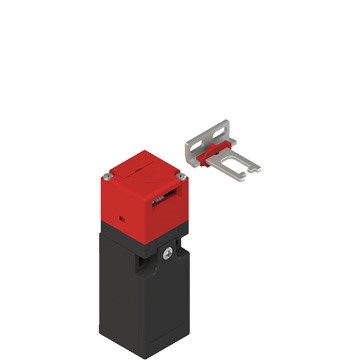

3. Pizzato FR 2093-D1 safety device:

Pizzato safety device is a device with its own actuator to help protect the machine’s working process, avoiding outside intrusion whether unintentionally or intentionally.

Characteristics:

| 1 | Bark | Polymer housing, one PG 13.5 conductor (FR series) |

| 2 | Contact block | 1NO + 2NC slow action (B20) |

| 3 | Head | Not separate |

| 4 | Key | Angled |

| 5 | IP protection index | IP67 theo EN 60529 |

| 6 | Positve | yes |

4. Light Curtain – curtain-type safety sensor

To optimize the robot’s working process, VULETECH integrates the Light Curtain device, a membrane safety sensor imported from Panasonic to help ensure safe contact in hazardous areas in production.

In addition, VULETECH also integrated PATLITE’s LR6 _02LJB tower light shelf. This buzzer device informs the operator about the current operating status of the Robot.

5. Patlite Light Tower

- The lights are simply connected to the Module, the light color modules can be reversed to different positions according to the user’s requirements easily and conveniently.

- The lamp’s protection level reaches IP65, making the light work well in all indoor and outdoor environmental conditions.

5.1 Specifications:

| 1 | Siries | LR6 |

| 2 | Size | Ø60 mm |

| 3 | Tiers | 3 |

| 4 | Light source | LED |

| 5 | LED Color | Red, amber, green |

| 6 | Sound level | 88 dB (1m) |

| 7 | Applicable electricity level | 24V DC |

| 8 | Protection level | IP 65 |

6. Máy hàn hai đầu board mạch điện tử hoàn chỉnh do VULETECH lắp ráp: