As automation becomes the new normal for manufacturing and warehouse operations in the age of Industry 4.0, technologies such as driverless forklifts, robotic arms, advanced sorting/picking, and intelligent conveyors Smart is increasingly popular while costs decrease; make choices more accessible to every company regardless of size.

One of the advancements that has attracted a lot of attention lately is the introduction of Automated Mobile Robots (AMRs) as a smarter, more flexible alternative to Automated Guided Vehicles (AGVs) for many material handling operations. If your business is looking at these options for adoption in its operations, you first need to understand the difference between these two automation options.

What is AGV?

An Automated Guided Vehicle, or AGV, is an industrial vehicle that can be pre-programmed to transport goods in a warehouse or manufacturing environment.

Autonomous vehicle AGV KUKA

- Điều hướng: Theo truyền thống được dẫn hướng bằng dải từ tính hoặc dây dẫn được lắp đặt trên hoặc dưới sàn nhà kho

- Triển khai: Yêu cầu cài đặt các hướng dẫn điều hướng, đôi khi yêu cầu cải tạo cơ sở đáng kể

- Tính linh hoạt trong hoạt động: Việc thay đổi mô hình hoạt động AGV yêu cầu lặp lại toàn bộ quá trình triển khai

- Khả năng đáp ứng: Tính linh hoạt hạn chế để thích ứng với môi trường thay đổi hoặc quy trình làm việc thay đổi

AMR là gì?

Robot di động tự động hay AMR là một phương tiện sử dụng các cảm biến và bộ xử lý trên bo mạch để tự động di chuyển vật liệu mà không cần đến các hướng dẫn vật lý hoặc điểm đánh dấu. AMR tự tìm hiểu môi trường, ghi nhớ vị trí và tự động lập kế hoạch đường đi của nó từ một điểm tham chiếu (một vị trí hoặc điểm đến trong môi trường) đến một điểm khác.

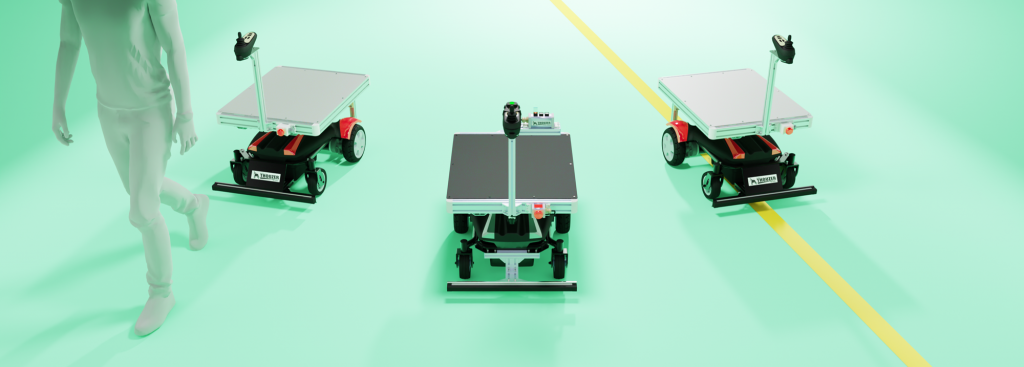

Robot di động AMR DOOG

- Navigation: Using technology like LiDAR sensor & Simultaneous Mapping and Mapping (SLAM), AMR will determine the best route between waypoints

- Implementation: This may vary, but great AMRs can be unboxed and up and running in under 15 minutes

- Operational Flexibility: An AMR will automatically plan the shortest path based on current conditions and requirements, if the work changes from day to day, the route of the AMR will change follow

- Ability Feedback: AMR will automatically sense and avoid obstacles and blocked passageways to find the best route to its next waypoint

Cost difference:

When deciding between AGV and AMR, you may be inclined to a lower-priced solution. However, there are other factors that will affect the overall cost of a mobile robot and the potential return on investment for your company.

AGV:

While AGVs typically have a lower cost per robot than AMRs, you must also consider the costs you will incur to set up, deploy, reconfigure, and operate them. AGVs typically require the installation of physical guides, underfloor wiring, or surface tape to allow the AGV to navigate and position itself in its surroundings. And if you need to install sensors underneath the floor, that means hours of renovation, plus the cost of the actual work.

Once you have prepared the physical environment, you must implement the AGV into your operation on a predetermined route based on the work being done at the time. The AGV will run on a set route unable to navigate around unexpected obstacles that stand in its way. Normally, the AGV will stop completely until the path is completely cleared. And if your environment changes or your work changes, you will incur additional costs to reconfigure your system and repeat the deployment process.

AMR:

In contrast, a great AMR requires no changes to your existing facility and can automatically navigate through production spaces and warehouses. It learns its environment, remembers its location, and automatically plans its path from one destination to another. If its path is blocked, the AMR can reroute itself without assistance.

The sensors that the AMR uses for navigation ensure that it can safely operate in dynamic environments with people and material handling equipment. And because the AMR is not a fixed structure within the facility, it can be moved and redeployed with minimal cost as your business grows and changes over time. In fact, an AMR might operate in one part of the facility in the morning and be deployed to a completely different mission during the day.

Which one should you choose?

AGV – Useful but Limited

If your company rarely changes, in terms of products manufactured, your operating processes or your workforce, then an AGV might be a good fit. However, if you are in the majority of manufacturers and warehouses that notice a rapid change in their material flow, work station or product mix, all of those changes require a robot. Smarter may change according to you.

AMR – Advanced, Flexible, Accessible

AMR is collaborative and agile to keep up with future opportunities in manufacturing and warehousing. They can avoid obstacles and relieve workers from repetitive or unproductive work so these workers can focus on valuable and fulfilling work. better.

Most importantly, AMR easy to set up and use allows immediate ROI. If workers can open the box and start using the automatic mobile robot in less than 15 minutes without the robot installing it; then they are empowered to use these tools with confidence and pride in making their company more efficient and competitive.

Flexibility, advanced navigation, and ease of deployment make AMRs the perfect solution to help you start automating your dynamic operations and empower your valuable workforce. work today.

—————

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

—————

Follow VULETECH at:

► Facebook: Vuletech

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw

Cre: Waypointrobotic

Translate: Vuletech