Over the past two years, as all parts of the world have been affected by the COVID-19 pandemic, supply chain operations, from production, to transportation, to distribution and storage, have suffered some of the same. department. With social distancing everywhere and people forced to stop working, warehouses face an extremely difficult challenge: How to continue operating while keeping everyone safe. ? And the seemingly impossible answer has a very easy answer, which is: automation.

Warehouse automation:

Warehouse automation or smart warehouses use storage racks that can be easily upgraded, operated and improved in capacity. With this model, everything will be combined with automatic loading and unloading robots, AGV self-propelled vehicles, cranes, conveyors to move goods to packaging lines. In addition, to manage all of the above, control software and information storage are indispensable.

This model is evaluated as an indispensable part of the digitization factory. This system uses almost no human labor.

Various automated systems have become popular around the world. However, the increasingly complex pandemic has shown us the advantages of new technologies that can help warehouses make big changes. These are all advanced technologies that follow new trends and innovations in warehouse automation that businesses should consider to apply to their operations.

Collaborative Robots:

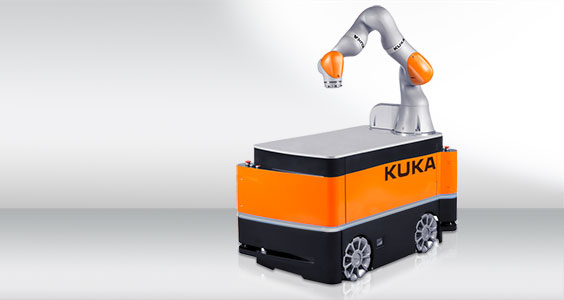

Collaborative robots (Cobots) are automated solutions designed to work alongside a human workforce, making work easier by completing monotonous or physically demanding tasks. Sometimes these Cobots are integrated into the AMR/AGV to form a mobile controller that can be a multiplier for the cobot operation and mobility of the AMR/AGV. These cobots help optimize warehouse operations while assisting humans in their skilled work.

Cobot combines AGV Kuka

Một số lợi ích ban đầu mà nhà kho nhận được từ việc triển khai cobots bao gồm:

- Cải thiện an toàn

- Cải thiện điều kiện làm việc

- Tăng cường tính linh hoạt

- Tăng hiệu quả

- Tăng thông lượng

Robot di động AMR

Khi làn sóng công nghiệp 4.0 nổ ra thì cũng là lúc các nhà máy ngày càng áp dụng tự động hóa vào dây chuyền sản xuất. Cùng với các Robot công nghiệp thì Robot di động AMR cũng ngày càng được ưa chuộng vì tính thực tiễn và đem lại nhiều lợi ích trong nhà máy.

Robot di động AMR DOOG

AMR is a robot that can understand and move on its own in its environment without direct human supervision or on a predefined path.

Warehouse workers know all too well how far they can line up to push carts around the facility. But now, warehouse automation has allowed that task to be transferred to AMR mobile robots, so workers can focus on other tasks and add value to the warehouse.

Read more about AMR Mobile Robot: https://vuletech.com/robot-amr-trong-nha-may-thong-minh/

Self-propelled robot AGV:

Autonomous vehicle AGV is a type of automatic cargo transportation robot that is present in most smart factories (Smart Factory) in general and logistics systems around the world in particular. Currently, we can see AGV self-propelled vehicles anywhere, from production lines, assembly lines, finished goods warehouses, e-commerce warehouses to supermarkets, trade centers or even stores. hospital, airport, etc.

See more about Autonomous Robot AGV:

Conveyor solutions:

Modern warehouses have to be quick to lay out, and that has given rise to flexible and automated conveyor systems. Traditional stationary conveyor systems mean that warehouse layouts and workflows can never be changed, or if they do, they require extended downtime and downtime.

Advances in flexible powered conveyors have given warehouses more options for automating material flow. And warehouses can take advantage of new technologies, such as warehouse robots with on-conveyor modules, to work with existing conveyor systems so that workflows can grow and scale. tissue when production required.

AS/RS . system:

Automated storage and retrieval systems, including automatic conveyor systems, loading conveyors, lifting systems, cranes, etc. have been around for many years, and although they have been completed successfully capabilities and accuracy, but they are still often considered expensive, cumbersome, and generally inflexible technology. Having said that, nowadays, AS/RS, is getting more and more beautiful and still gives users all its original benefits, such as: reducing/limiting labor costs, flexibly changing with ability from its modular structure, and of course increased accuracy.

Pallet transport robot:

Transporting pallets can be one of the most time-consuming and physically demanding jobs in a warehouse environment. To improve efficiency and enable employees to work with more added value, many organizations are turning to pallet transport robots. These warehouse robots can locate and transport large volumes consistently throughout the day and even outside of business hours. The Ideal Pallet Robot will have several attributes that make it easier to integrate into a warehouse operation, such as:

- Natural features or SLAM . navigation

- Dynamic path planning

- Multi-directional navigation

- Automatic charging

- Flexible top modules for material loading and unloading

- Automate the picking process

Pick-up is one of the most time- and energy-intensive tasks in a warehouse operation – in fact, it accounts for 50% of the entire fulfillment process, consuming precious time and money. With new automated warehouse solutions, such as cobots, automated forklifts and trolleys, automated mobile robots and mobile conveyors, the picking process can become almost fully automated. With these solutions, workers can spend less time on picking and more time handling other tasks that are more complex and valuable to the entire warehouse.

There are various tools that can be used to enhance the picking processes. For example, voice automated order picking, robot-robotic order picking. And pick-to-light (Pick to light is a light direction selection technology that provides an accurate and efficient method of paperless placing or sorting and assembling products.) . These technologies also utilize advanced barcoding options that integrate seamlessly with your chosen management software for the fastest, most accurate automated reporting experience.

Industrial IoT:

The Internet of Things or IoT is a broader concept than a single technology, but it is often included in the most efficient smart warehouses in the world. As IoT is used to control so many moving components, both automated and manual, it can optimize all your processes so their data lives in an easily accessible network. This optimizes the warehouse’s inventory control process, the workforce planning of warehouse managers and operators, and of course, an overall better customer experience through successful completion rates. work faster and more accurately.

Ability of extension:

If the global pandemic has taught us a lesson, it’s that we need to be prepared for anything, and that’s certainly true when it comes to warehouse operations and fulfillment. Automated warehouse solutions can dramatically improve many functions, but can be frustrating if these tools and technologies are not designed to adapt and evolve as needed.

Scalability – when it comes to warehouse, robotics and storage automation – means having solutions that are easy to reconfigure, scale up or down, and can be made to fit the operation. yours and not vice versa. Flexible solutions, such as autonomous mobile robots, allow companies to adapt warehouse operations to fluctuating demand, taking the pressure off workers in the process.

—————

Vu Le Technology Company Limited – specializes in industrial automation equipment, factory automation solutions and robotics.

Address: 27 Xuan Quynh, Gia Hoa Residential Area, Phuoc Long B Ward, City. Thu Duc, HCMC

Hotline: (028) 3620 8179 / 3620 8176 / 3620 8177

Fax: (028) 3620 8178

Mail: info@vuletech.com

—————

Follow VULETECH at:

► Facebook: Vuletech

► LinkedIn: https://lnkd.in/e6rbG6e

► Youtube: https://www.youtube.com/channel/UCmHCn0T-oSbizOiWdYbRWzw